The off-highway machinery sector is rapidly adopting electrification due to regulatory pressures and the demand for sustainability. Although slower than other sectors, this transition offers a unique opportunity to implement proven technologies which will be discussed at the fourth virtual Future of Electrification conference, taking place 26-27 February.

A generational approach to electrification

The evolution of electrification in other sectors provides a roadmap for the off-highway industry. Early electric forklifts and indoor machinery paved the way for modern passenger EVs, proving emissions-free solutions in demanding environments. This pattern is now repeating, with off-highway electrification benefiting from mature electric technologies developed in other sectors.

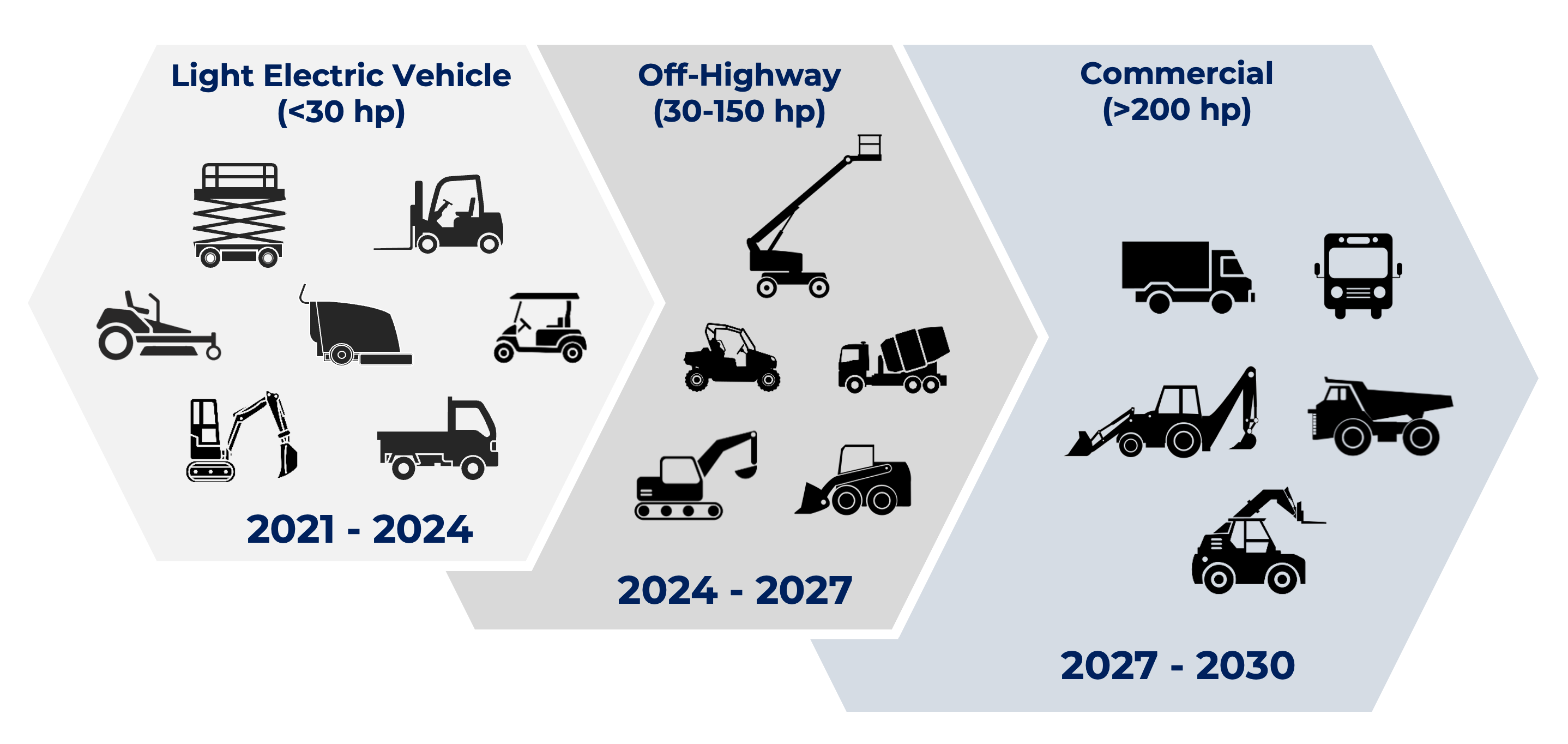

A three-part “generational model” for electrification can be observed:

- Generation 1: Initial designs using standard parts from other industries to create an electric drivetrain.

- Generation 1.5: An iterative phase refining designs to enhance performance, reduce costs, and delegate more tasks to suppliers.

- Generation 2: Full maturity, where third-party integrators manage optimized subsystems, allowing OEMs to focus on market-specific customization and seamless integration.

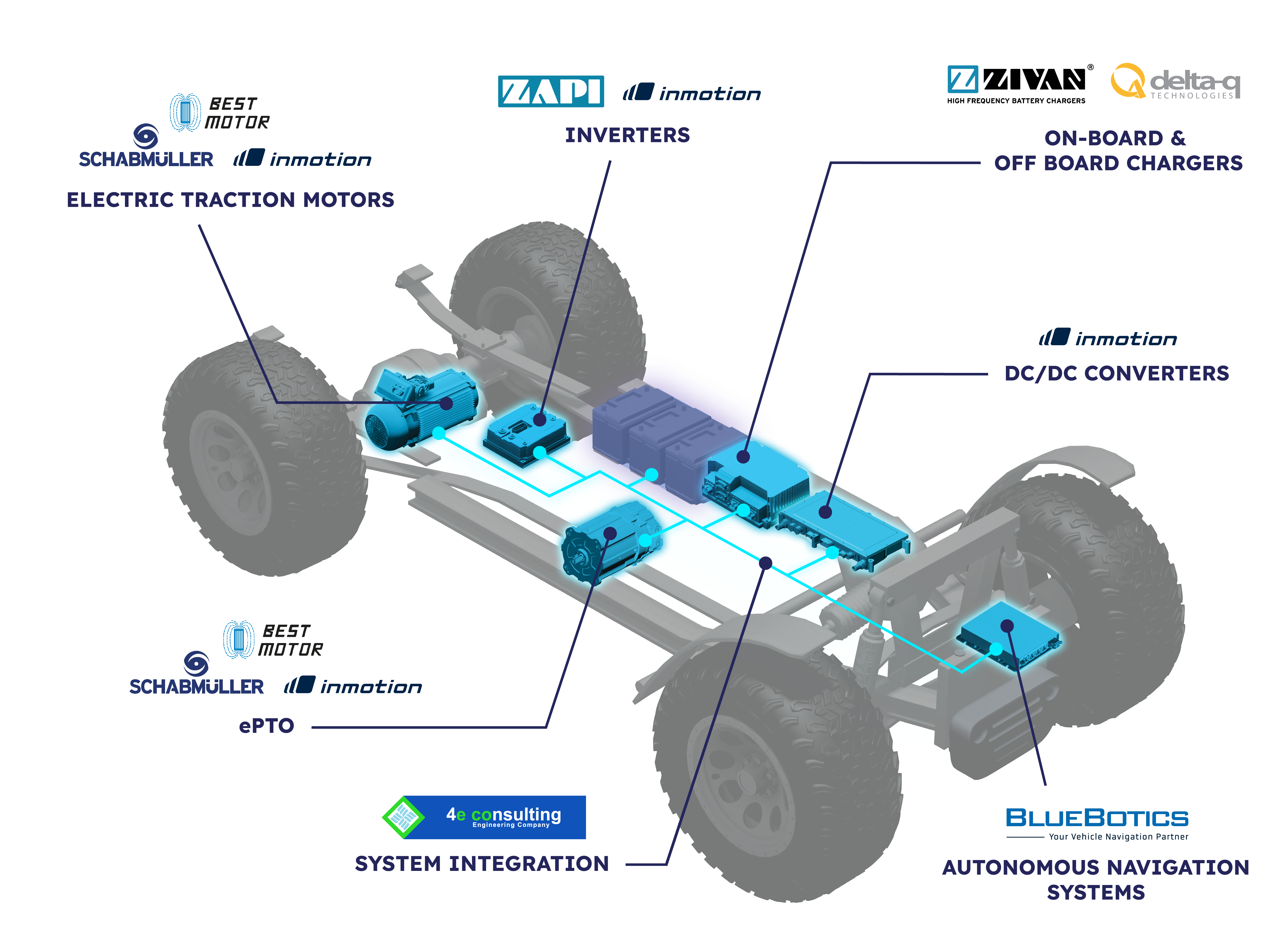

The ultimate goal is fully integrated drivetrains, where each component works in harmony for maximum efficiency.

The critical role of charging solutions

Selecting the right charging solution is crucial for achieving an integrated future for electrified machinery. A charger tailored to the specific machine application will improve battery efficiency, safety, and lifespan. Given that the battery is typically the most expensive component, protecting and maximizing its value through the right charger is critical.

On-board charging solutions bridge the gap between a machine’s battery and diverse charging infrastructures. However, it’s important to consider both on-board and off-board charging solutions, sizing the charger based on available connections, battery charge rates, and the operating environment.

Electrification trends and market factors

Vehicles are major contributors to greenhouse gas emissions, making electrification a key solution. The transition to electric vehicles (EVs) is occurring across various sectors, including industrial, off-highway, and automotive.

The off-highway sector is projected to see increased adoption of electrification from 2024-2027. A valuable case study can be found in the material handling sector, where electric forklift sales have surged by 140%, compared to only a 14% increase in internal combustion (IC) forklifts.

This growth is driven by several factors:

- Lower operating costs

- Reduced maintenance

- Increased productivity

- Enhanced operator comfort

- Regulations like the CARB IC forklift ban

While higher upfront costs and charging infrastructure remain hurdles, the market is clearly shifting towards electric solutions.

Emerging technologies and real-world applications

Several technologies are transforming electrification:

- Gallium Nitride (GaN) and Silicon Carbide (SiC) are enhancing power electronics by minimizing losses and boosting performance.

- Lithium batteries offer higher energy density and integration capabilities for industrial machinery.

- Battery management systems (BMS) improve safety, provide maintenance insights, and optimize charging profiles.

- CAN bus protocols enable remote fleet monitoring and management, streamlining operations and reducing downtime.

Overcoming challenges through integration and collaboration

Integrated electric drivetrains differ from internal combustion engines, where each component enhances the performance of the others. This interconnectedness requires OEMs to balance flexibility and cost efficiency.

- Non-integrated setups: Offer flexibility but incur higher upfront costs.

- Fully integrated solutions: Are cost-optimized but lack flexibility for independent upgrades.

The key is strategic collaboration with electrification experts. By leveraging cross-industry insights and supply networks, OEMs can develop tailored electrified solutions. Engaging suppliers early in the design process ensures manufacturable specifications and realistic performance expectations.

ZAPI Group are system integration specialists and have a highly integrated product portfolio, including:

- Motion controllers

- Electric motors

- High-frequency battery chargers

- Autonomous navigation software for full-electric and hybrid applications

Electrification: A necessity for the off-highway machinery sector

Electrification is no longer optional for the off-highway machinery sector; it is a regulatory and operational necessity. As the industry moves toward fully integrated solutions, early collaboration with electrification experts is essential for a seamless transition to an all-electric future.

Electrification is not just about powering machinery; it’s about powering progress. OEMs that embrace these technologies with the right partners will lead the way. The off-highway sector can leverage the progress made in established ecosystems like the Material Handling industry.

The fourth virtual Future of Electrification conference, taking place 26-27 February, 2025, will explore these themes and more. Registration is free and open to all iVT International readers.