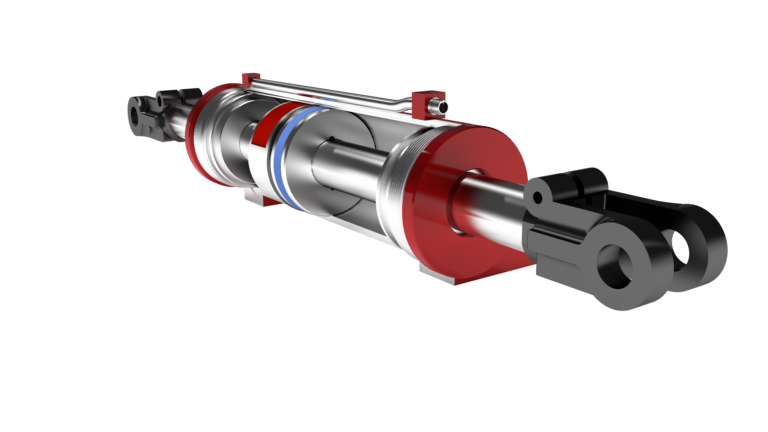

Since its introduction in 2008, Rota’s external sensor technology has revolutionised how position sensors are implemented in hydraulic cylinders. Initially designed to propagate a magnetic field through a carbon steel cylinder wall, this innovation enabled accurate analogue or digital position reporting for cylinders where traditional methods such as deep drilling were either not possible or economically viable. With the latest advancements, including a reduction in magnet size by up to 88%, the new Elu Series offers even greater potential for cost savings and operational efficiency. This makes it an ideal solution for OEMs in industries like transportation and agricultural machinery.

The evolution of the Elu sensor

Rota’s initial design addressed the challenge of integrating sensors into double-ended and long-stroke cylinders, where traditional deep drilling could compromise the structural integrity of the cylinder or increase costs. The El series enabled external sensor mounting, eliminating the need for internal modifications. This breakthrough opened opportunities for precise position tracking in heavy-duty applications, such as steering systems in agricultural machinery or long-reach hydraulics in transportation vehicles.

With the latest Elu series, Rota has taken this concept even further. By reducing the magnet size by up to 88%, the new sensor allows for integration into even smaller cylinders without altering the core dimensions – such as the pin-to-pin length – critical in many OEM designs. This flexibility enables seamless integration into existing systems, making it a plug-and-play solution for manufacturers.

Cost benefits

One of the most significant cost-saving aspects of the Elu sensor is the minimal machining required. Installing the magnet involves milling a simple slot in the piston, at a cost of approximately one euro per cylinder. This is drastically lower than traditional methods, such as deep drilling, which not only incurs higher costs but also compromises piston rod strength.

In long-stroke cylinders, gun drilling is often necessary to accommodate traditional internal sensors, a process that can be prohibitively expensive. By eliminating this requirement, the E Series provides a solution that cuts down on both time and costs, making it feasible to implement position sensing even in long-stroke or double-ended cylinders.

The ability to pre-install magnets in cylinders and add sensors later, as needed, creates a highly flexible manufacturing process. OEMs can standardise their cylinders across different models and decide to add sensors only when the application requires it. This “modular” approach can lead to significant inventory cost reductions, as the same base cylinder can be used across various configurations. Furthermore, the smaller magnet size means the Elu sensor can fit into most cylinder designs without requiring changes to the overall dimensions, making it easier for OEMs to integrate the technology without re-engineering their systems.

Greater potential

In industries like transportation and agriculture, where equipment durability and precision control are paramount, the Elu series offers critical advantages. For instance, in agricultural machinery, where precise steering and hydraulic control are necessary, the Elu sensor allows for real-time position monitoring of cylinders, improving operational efficiency and reducing wear and tear on machinery. Similarly, in heavy-duty transport vehicles, where hydraulic systems are integral to lifting and loading mechanisms, the Elu sensor provides robust, reliable feedback, enabling smoother operations and improving safety.

The rugged design of the Elu sensor, coupled with its resistance to vibration and harsh conditions, makes it ideal for outdoor and high-intensity applications where downtime can be costly. Additionally, the easily replaceable sensors mean less downtime and lower maintenance costs ensuring higher productivity for end-users.

With the new Elu series, Rota has not only advanced the technology behind external sensors but also made it more accessible and cost-effective for OEMs in transportation and agricultural machinery. The reduced magnet size, lower machining costs, and modular integration potential offer a clear path to improving operational efficiency and lowering overall production costs. As the demand for smarter, more efficient machinery grows, the Elu series sensor positions itself as a crucial innovation that can help manufacturers stay competitive while meeting the needs of increasingly sophisticated applications.

Rota will be exhibiting at EIMA International 2024 – Hall 15 Stand D/10