From USB-C chargers to level sensors and display instruments, Motometer has developed an electronic ecosystem integrating measurement and operational monitoring

Specialising in vehicle electronics, displays and tank gauging, Motometer provides reliable, optimum solutions for construction and agricultural machinery, municipal and special vehicles, trucks and buses, as well as several other mobile machines.

Electronics: control and regulate

Motometer’s electronic components for commercial vehicles and mobile machines are characterised by a long service life and reliability under all conditions.

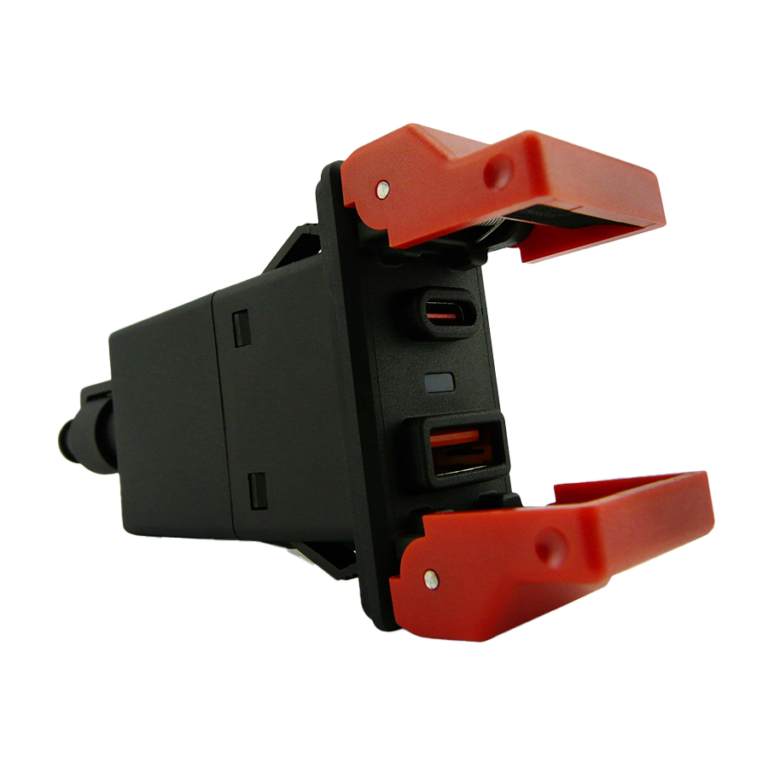

Motometer’s innovative USB-C charger enables its customers to discover the future of charging. It comes equipped with two powerful USB 2.0 ports enabling the simultaneous charging of two devices via a type-a and a type-c output. Moreover, the LED status indicator makes it easy to use, even in the dark or areas with limited visibility.

Thanks to its standardised design, the USB-C charger can be easily integrated into a rocker switch panel. The robust sealing caps and the waterproof plug on the back ensure reliable protection against water, dirt, dust and debris, while the charger works without any problems with a supply voltage of 12 and 24 volts. Even at operating temperatures of -20°C to +60°C, its functionality remains unrestricted. With Motometer’s USB-C charger, users can optimise their charging processes and benefit from the convenience and efficiency of this innovative charging solution.

Sensors: measure and record

Motometer sensors deliver exact values even under demanding conditions. The precision products impress with the consistently high quality of all components, durability and resistance, even when subjected to surge forces. In addition to standardised sensors, Motometer also prioritises customer-specific requirements in small series production. Depending on the desired measuring range and technical criteria, a wide variety of sensors are available.

Motometer‘s portfolio of level sensors includes immersion tube sensors with reed contact – the perfect solution for vehicle tanks with a depth of up to 1300mm. Depending on the size of the mounting opening or flange plate, the range includes immersion tube sensors with flange diameters of 54mm or 80mm, as well as metal or plastic versions.

The immersion tube and tank sensors, depending on the product specificity, operate at temperatures of -40 °C to +85 °C and have a voltage range of 6 to 24 volts. The product range offers tank sensors with suction and return pipes, with bolt circle or bayonet, as well as with or without auxiliary heating.

Motometer also offers ultrasonic technology with Motosonic. This generates high-frequency sound waves which are sent to the liquid surface and measure the transit time required for the round trip between the sensor and the liquid surface. By accurately measuring the time and speed of sound, the Motosonic reliably calculates the distance between the sensor and the liquid surface and thus the fill level of the tank contents. The Motosonic takes factors such as the tank shape, surface structure and possible reflections in the tank into account during the calculation. Compared to other tank sensors, the ultrasonic content measurement offers a remarkably high accuracy of ±2.5mm and a resolution of 1.8mm. In addition, the measurement is contactless, avoiding the wear and tear effects that can occur with mechanical measurements.

Display instruments: check and inform

The measured information is displayed reliably and accurately in the cab thanks to the variety of Motometer display instruments, creating the basis for professional and efficient use in machines. The individual components can be perfectly integrated into your vehicles through to the consistent use of open and standardised interfaces.

By choosing Motometer products, a flawless cycle within the measurement, control and display technology of a vehicle is guaranteed.