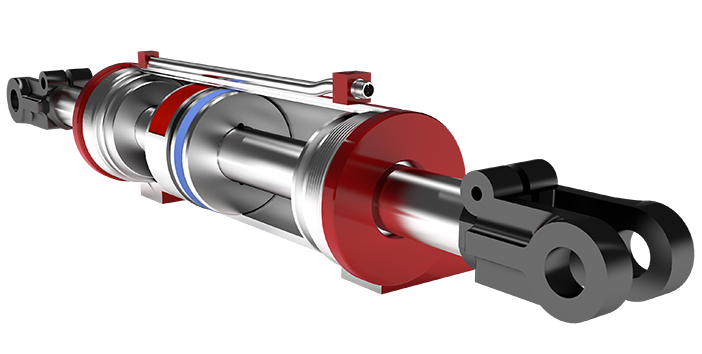

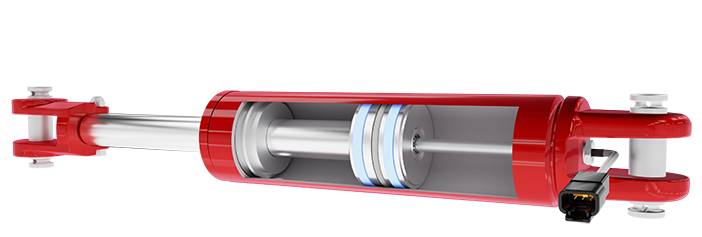

Rota Engineering designs and manufactures the smallest, most robust linear transducers for position control and monitoring of hydraulic cylinders. These sensors have been specifically designed for the mobile hydraulic cylinder market to withstand both physical abuse and exposure to dust, water ingress. In addition to internal sensors, Rota has patent applied for technology where the sensor can be mounted externally, designed for double rodded or through-rod steering cylinders and longer stroke cylinders.

Rota also manufactures tank level sensors that utilize proven Hall Effect technology, used successfully in linear position sensors for over 15 years. Early designs for U.S. nuclear submarine ballast tanks laid the ground work to expand this product offering to mobile liquid level transducers for fuel, hydraulic oil, chemical tanks, etc. Now this sensor has added the capability of a dual output, level and temperature, in one package when utilizing a digital output.

Features of this product are:

- Improved accuracy so operators can better monitor hydraulic tank level and temperature in one sensor

- Transducers are capable of 75 g shock and 25 g vibration with greater than 60-year MTBF for long life

- All welded, rugged stainless-steel construction

- IP69K OPEN FACE high pressure wash down compatible

- Up to 3 m in length

- European and North American approvals

- Flexible factory design allows for end user customisation

- Quick delivery at a competitive price

Rota Engineering designs and manufactures linear transducers for tough applications where robustness is required. Transducers can be designed up to 130 ft in length, for use 20,000 ft below the surface of the ocean, for hazardous environments and has voltage, current, PWM and CANBUS, CANOPEN, ISOBUS output options.

Rota sensors are tested for compliance to the requirements of:

- UN ECE Reg. 10.05: October 2014 (AUTOMOTIVE)

- EN ISO 14982:2009 (AGRICULTURAL AND FORESTRY MACHINERY)

- ISO 13766:2018 (EARTH-MOVING AND BUILDING CONSTRUCTION MACHINERY)