Danfoss is working with Iowa State University to build a state-of-the-art testing facility for off-road vehicle chassis. The new chassis dynamometer will be located near the company’s North American office in Ames, Iowa.

“We are pleased the new chassis dynamometer will provide the research and educational facilities necessary to foster breakthroughs in new engineering technologies for Danfoss,” said Dave Wohlsdorf, senior director strategic innovation at Danfoss Power Solutions.

Expanding capabilities

Partnering with Iowa State University enables Danfoss to further expand its research and testing capabilities in North America. Insights gained on the Iowa State campus with this new technology will complement field testing conducted at the Ames site allowing Danfoss the opportunity to implement industry-leading solutions at a faster rate for its customers.

Testing and simulation is an important part of the engineering and development process — whether for a new component or a revamped machine design.

“Comprehensive testing can reduce design cycles and speed up research and development, which translates to saved time and money for our customers. That’s why Danfoss has made it a priority to stay on the leading edge of testing and simulation technology,” added Wohlsdorf.

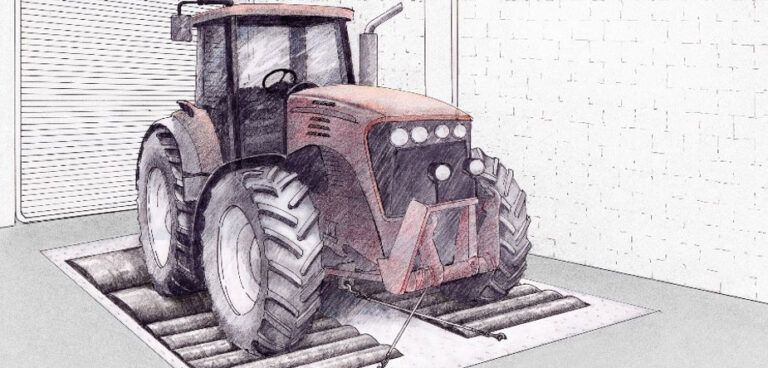

The dynamometer will allow for controlled, dynamic testing of complete off-highway vehicles with advanced traction control systems. The facility is designed to test vehicles up to 350kW and 70km/h, and offers independent monitoring and loading of each wheel. No other laboratory is built to handle tests of this power and speed.

Danfoss and Iowa State will officially break ground on a new state-of-the-art testing facility on October 5, 2018, with a target completion date in summer 2019. The facility will be available for use by Danfoss, machinery OEMs, students and researchers.