Dutch feed machinery specialist, Trioliet will launch its new and higher capacity feed robot at EuroTier in November.

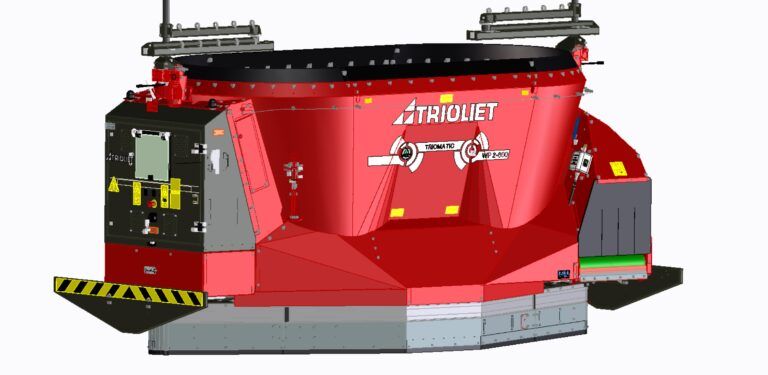

To boost feeding efficiency on the farm Trioliet has doubled the maximum capacity of its Triomatic feed robots to six cubic metres on the new WP 2 600 model.

This new machine has a maximum load capacity of 2,000kgs, making it more suitable for the bigger farms with 600 to 800 cows.

Using the Trioliet batch and traffic manager, it is also possible to scale the system’s capacity to a maximum of four robots, making automatic feeding accessible for farms with 1,200 to 2,500 cows.

The mixing tub of the Triomatic WP 2 600 is equipped with two vertical augers made of wear-resistant stainless steel.

Even small quantities are homogeneously mixed thanks to the dual flow principle. With the help of counter blades in the mixing tub and knives on each auger, the feed is also well chopped.

Energy is saved on the Triomatic WP machines when dispensing, as only the auger closest to the discharge gate is activated. The second auger is only engaged when the feed amount falls below a certain level. Discharge is done via a cross conveyor belt.

All settings can be entered directly via the large touchscreen on the robot, but also via a computer, smartphone, or tablet. The feed robot is loaded by a Trioliet feed kitchen of choice: the Triomatic T10, T20, T30, or T40.

Trioliet says its Triomatic automatic feeding systems provides users with a great deal of flexibility and typically results in labour savings of up to 80% on the feeding process.

The official introduction of the WP 2 600 will be at Eurotier 2024: Hall 27, Stand G24.