GKD Technologies, a market leader in the design and manufacture of connected, modular safety systems for NRMM (non-road mobile machinery), has introduced the Series 2HS, a new safety system for reliable height and slew control, designed specifically for the construction industry.

Improving worker safety is an absolute focus for the construction industry, with contractors, plant hirers and UK agencies mandating a range of safety products and training programs to best manage their associated risks. The Health and Safety Executive (HSE) identifies moving, slewing, and working as the time when most fatal and serious injuries involving excavators occur. In the context of construction-specific data, it shows that 22% of worker fatalities and can be linked to a moving vehicle or object and 12% of non-fatal injuries.

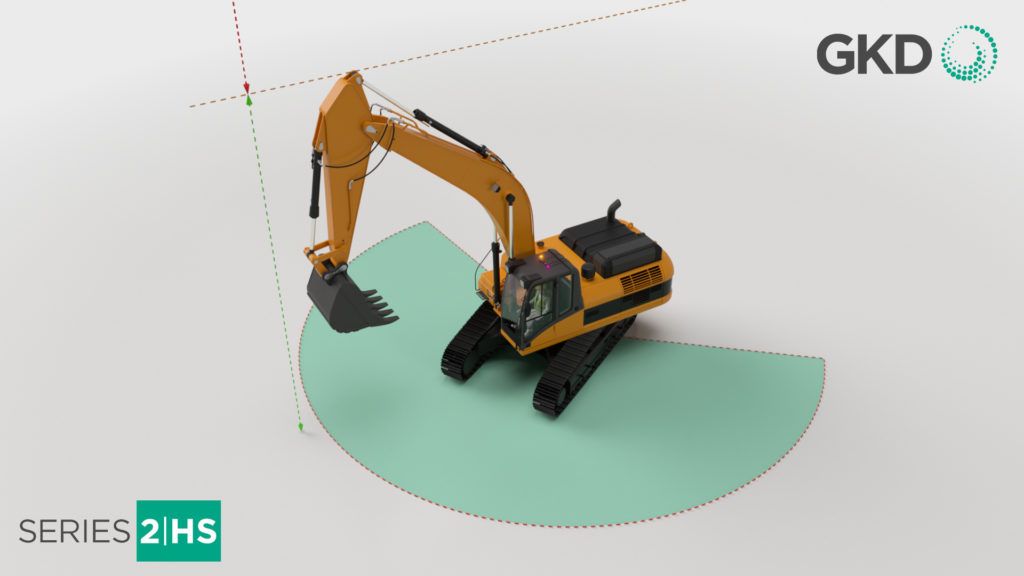

Above: the GKD Series 2HS enables the machine operator or site manager to set safe working height and slew limits for heavy machinery

Above: the GKD Series 2HS enables the machine operator or site manager to set safe working height and slew limits for heavy machinery response to customer feedback on GKD’s previous height and slew solution, the Series 2HS has been developed on the company’s most reliable and robust software platform. It provides intelligent height and slew limiting, using dedicated high accuracy sensors and GKD’s proven safety focussed software and with an easy-to-use interface, the system provides visual and audible warnings when limits are approached. The system is designed to pre-empt movement, ensuring that limits are anticipated, and motion cuts are implemented so that the pre-set limits are not reached but the machine is still able to move within safe limits.

The GKD Series 2HS is a practical and effective way of monitoring and controlling the working height and rotation of machinery to ensure safe operation on site. It enables the machine operator or site manager to set safe working height and slew limits for heavy machinery, either dial in or manually, ensuring site hazards or risks are avoided. The system is both versatile and adaptable and has been designed to keep personnel safe, protect machines and the surrounding infrastructure at the worksite.

Above: the Series 2HS can be installed on tracked or wheeled excavators, backhoe loaders and a range of other machines

Above: the Series 2HS can be installed on tracked or wheeled excavators, backhoe loaders and a range of other machinesThe Series 2HS offers the unique flexibility of parallel or multipoint virtual walls which is ideal for working in confined surroundings or close to open traffic lanes, and when combined with height limits, is the ideal system for working under overhead obstructions. This function increases the usability of the machine and allows for optimization of the ‘working area’.

The Series 2HS can be installed on a range of construction machinery, including tracked or wheeled excavators, backhoe loaders, and other articulated boom machines. Such is its versatility it can also be fitted to multiple boom configurations, including multi-section, swing, and offset booms.

The system benefits from a ‘supervisor key switch’ which enables limits to be set and not overridden – therefore ‘tamper proof’. A ‘disable key switch’ allows the system to be switched off when not required.

Additional benefits to the user include digging depth indication, which helps to reduce the over-digging of trenches. This function is activated by simply switching between lifting and digging modes and enables the operator to monitor and set dig depth limits supporting efficient and accurate digging. This dig once, move once approach means the operator is working smarter not harder!

The Series 2HS uses a compact fully responsive touch-screen display which is operator-friendly. The 4.3 inch, high brightness LCD touch screen provides the operator with an easy-to-read graphical interface that displays both height and slew parameters and with interactive menu screens for easy selection and setting of features.