For the first time, MAN Engines is presenting possible ways for sustainable propulsion systems as well as solutions for stationary energy storage.

The company’s goal is to transform its portfolio so that it offers its customers solutions in agricultural and construction technology, for watercraft and in power generation that do not release CO2 locally.

According to Mikael Lindner, head of MAN Engines, its ambition is to use its products and services to simplify the business of large and small OEMs towards decarbonisation.

The path to the future is clearly defined at the parent company MAN Truck & Bus: “MAN is accelerating its transformation and taking big steps towards emission-free drives. The focus at MAN Truck & Bus and the TRATON Group is clearly on battery-electric drives,” says Alexander Vlaskamp, Chairman of the Executive Board of MAN Truck & Bus SE. “Recently, however, we have also stepped up our R&D efforts in the hydrogen sector and built a truck prototype with a hydrogen-based combustion engine for future niche applications and for off-road propulsion, for example, or at sea,” says Vlaskamp.

As a business unit, MAN Engines is clearly also following this path and draws on this in-house knowledge, decades of industry and service experience, but also external know-how from experienced partners in the development of future technologies. MAN Engines’ customers come from very heterogeneous industries with different requirements for the drives, different availability of fuels and different available installation space for energy storage systems. In the medium and long term, a wide range of drive concepts will therefore be available. “In the future, MAN Engines will rely on pure combustion engines for hydrogen and regenerative fuels, battery storage systems and also complete electric drive systems to operate vehicles and machines locally with the lowest CO2 emissions to meet the various requirements,” explains Mikael Lindner.

MAN Engines envisages the following technologies in its portfolio in the short, medium or long term to support customers in decarbonizing their products:

Battery storage and integrated e-drive systems

At the IAA Transportation 2022, MAN Truck & Bus presented the near-production prototype of the new MAN eTruck, which will make its market debut from 2024, to a large international audience for the first time. With a daily range of up to 800 kilometers and megawatt charging capability, the new eTruck will not only electrify long-distance transport, but also all common transport areas covered by diesel trucks today. In 2024, the first heavy-duty eTrucks of series production will roll off the assembly line in Munich and onto the yard of the first customers. Today, more than 3,000 MAN Lion’s City E electric buses and MAN TGE vans are already on the road. In addition to MAN Truck & Bus’s electrical expertise, there are several million kilometres of the MAN eTGM medium-duty distribution truck, which this small-scale electric vehicle has “experienced” with a total of 60 customers since 2019.

For the batteries of the electric vehicles, almost 100 million euros will be invested in this important future technology at the MAN plant in Nuremberg, among other places. Here, battery packs are to be manufactured in in-house large-scale production. The capacities of the plants in Munich and Nuremberg are coordinated for this purpose.

In addition to their use in the Group’s own vehicles, these batteries will also be available to OEM manufacturers of agricultural and construction machinery as well as watercraft in the future. In the area of electricity storage, in addition to the use of new products (1st Life), the secondary use of batteries (2nd Life) also comes into play.

Hydrogen engine

At MAN, the hydrogen combustion engine is one of the most conceivable mobility solutions in various applications, for example in the maritime or off-road sectors, but also in the stationary sector for combined heat and power.

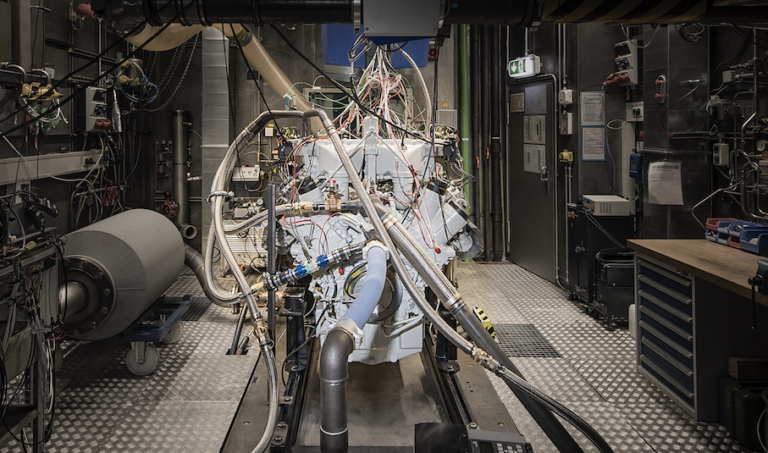

In the first step, a truck prototype has therefore already been equipped with a hydrogen combustion engine. It has been in testing since the end of 2021. At the heart of the demo truck is a 16.8 L hydrogen engine with approx. 500 hp and 2500 Nm based on the diesel engine kit. The expected service life is comparable to conventional combustion engines, even when using low-grade hydrogen. Thanks to the use of dual-flow cooled exhaust gas recirculation and a simplified SCR exhaust gas aftertreatment system, the prototype truck with the hydrogen combustion engine was recently approved as a ZEV (Zero-Emission Vehicle).

For the off-road sector, MAN Engines presented the prototype of a possible hydrogen combustion engine for a snow groomer at the Interalpin in Innsbruck in mid-April 2023: The vehicle concept of the PistenBully 800 from Kässbohrer Geländefahrzeug AG already takes into account the fact that there is room for a future hydrogen combustion engine – the MAN H4576 – and that corresponding interfaces are available. As a result of these preparations, the hydrogen engine should be able to replace the diesel engine in the PistenBully 800 in due course. The MAN H4576 is based on the basic engine of the MAN D3876 diesel engine and uses about 80% common parts. The assemblies for hydrogen supply and combustion, engine control and exhaust gas regulation are subject to significant adaptation and changes.