Liebherr has announced early trial results using Mahle Jet Ignition in the development of hydrogen-fuelled internal combustion engines. It proved to be a successful ignition source for hydrogen without the need to reduce compression ratios, unlocking the potential of hydrogen as a carbon-neutral fuel for the heavy-duty engine sector.

Hydrogen is a gaining attention due to its increasing availability and the fact it can be produced from renewable energy sources. As a fuel for proven and existing ICE technology in aggressive environments, hydrogen is ideally suited to the high load duty cycles with sudden load steps, heat, dust and vibration of heavy duty and off-road use – which is not the case for battery electric or fuel-cell powertrains.

“The use of hydrogen as a combustion fuel has the potential for rapid de-carbonisation of many heavyduty and off-road sectors,” says Mike Bunce, head of research for Mahle Powertrain US. “A wealth of research over the past few decades has confirmed the compatibility of hydrogen with internal combustion engines. The challenge has been to get it to run with stable combustion without resorting to reductions in compression ratios to avoid engine knock and pre-ignition. Our common work with Liebherr suggests we have the answer.”

The challenge is that hydrogen as a combustion fuel is highly prone to abnormal combustion, leading to engine knock and pre-ignition. Typically, this necessitates an inefficient reduction in engine compression ratio. However, a potential alternative is to depress combustion temperatures by using high levels of dilution, which is more conducive to stable running, but would require a high-energy ignition source.

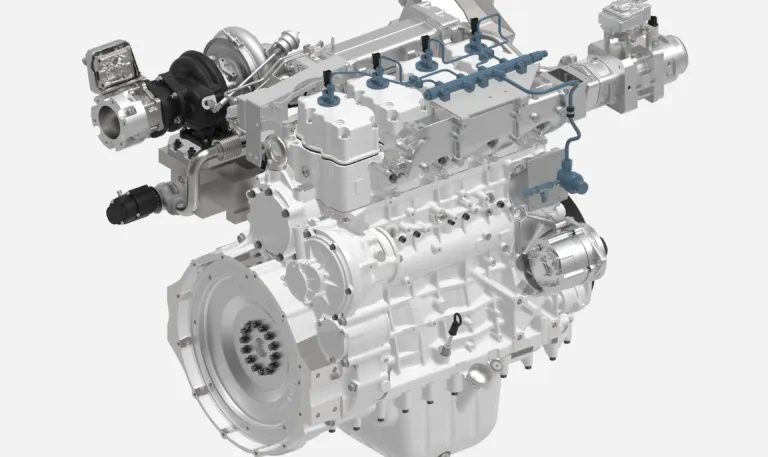

Originally developed for gasoline applications, Mahle’s pre-chamber ignition technology enables the use of highly dilute fuel/ air mixtures, making it ideal for use in hydrogen-fuelled engines. To achieve this, the MJI was adapted, mainly by modifying the pre-chamber in the cylinder head containing a spark plug, which ignites a fuel/ air mixture. The resulting gas plasma is forced through small orifices into the main combustion chamber to ignite the combustion mixture very quickly and uniformly.

Adaptation of the active pre-chamber to fit in Liebherr’s H966 and H964 engines has shown, in a preliminary investigation, that this technology extends the stable dilution limit of the engine well beyond the capability of traditional ignition systems, with much more rapid and complete combustion.

Some of the collaboration results to date were jointly presented at the 8th International Engine Congress in February 2021. The two companies are continuing their collaboration in order to push towards zero emissions vehicles that can meet the significant demands of the heavy-duty and off-road sectors.