Webasto, the systems partner for electric mobility, has released its Electrical Battery Thermal Management (eBTM) a compact and scalable system that keeps traction batteries in trucks, vans, buses and construction machinery within the ideal temperature range at all times. This allows the batteries to deliver their maximum operating performance, regardless of the outside temperature and load, and achieve the longest possible life cycle – it also facilitates more rapid charging.

Ideal temperatures for maximum capacity

The eBTM, which is precisely tailored to the requirements of traction batteries, allows continuous monitoring of the operating temperature and ensures that the heating and cooling circuits are balanced in order to maintain the battery temperature in the ideal range of approx. 22 degrees at all times. Depending on the vehicle type, application and number of batteries installed, several units can be combined. The eBTM dynamically adjusts the temperatures through the different load phases. It is moreover capable of conditioning the batteries during charging, thereby halving the charging time.

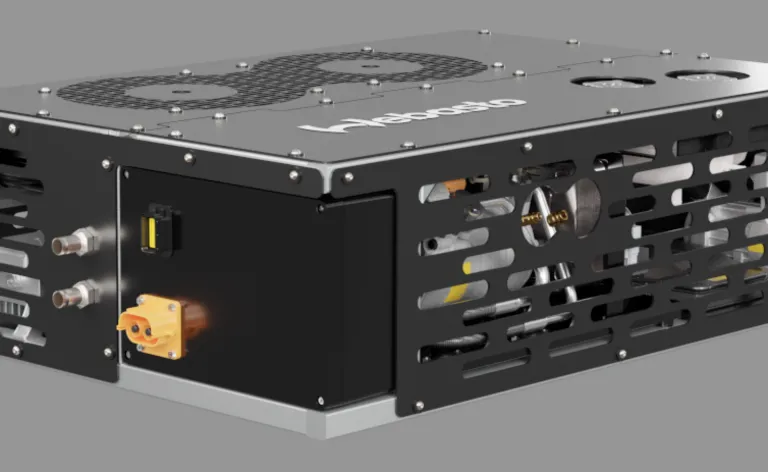

The system solution is designed for 400- as well as 800-volt applications and delivers up to 8 kilowatts (kW) of cooling and up to 10 kW of heating power for battery systems having a total capacity of up to 210 kilowatt hours (kWh). Thanks to its compact dimensions of 100 x 70 x 30 (L x W x H) centimetres, low weight of just 90 kilograms and just a few connection interfaces, the plug-and-play system is easy to install and can be taken into operation quickly. The components for the coolant and heating circuits, electric water pumps and control units are already fitted inside the eBTM housing.

Benefits in figures

The eBTM from Webasto is highly efficient, thereby saving essential battery capacity in everyday service. The solution allows batteries to be charged using up to 41 percent more power compared to batteries without thermal management. The accelerated power input results in a significantly reduced charging time. For a driving profile having a high frequency of starts and stops, thermal management provides 8.9 percent more range, resulting partly from 24 percent greater energy recuperation at low temperatures. Under hot climatic conditions, the eBTM furthermore improves the ‘state of health’ by 21%.

“The cornerstones of e-mobility are high-performance traction batteries that store the energy necessary for e-drives and deliver it at the push of a button,” asys Jörg Hornung, vice president business line thermal management at Webasto. “In order for the batteries to develop their full performance and ensure the vehicles and equipment function properly, the batteries must be operated within their ideal temperature range, regardless of ambient temperatures and load. While batteries that are too cold lose power, excessive heat can cause chemical degradation of the battery cells, which can reduce their service life. The eBTM allows us to deliver a sophisticated system solution to meet this challenge that harmonises optimally with our own traction batteries, but also with those of other suppliers.”