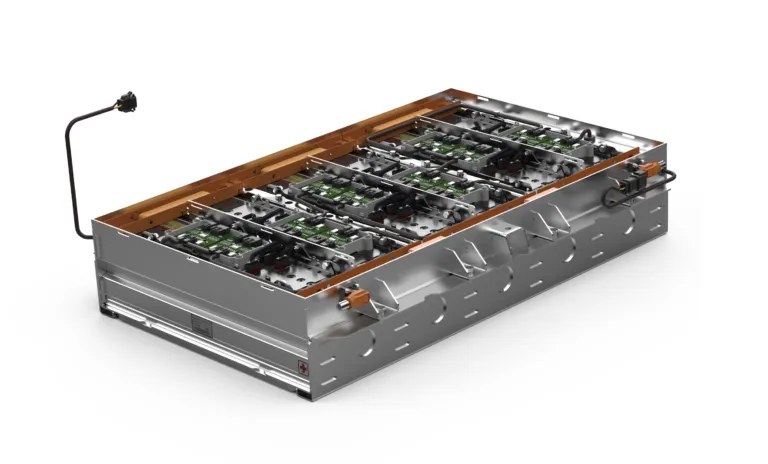

Finnish technology company Proventia has launched its ePRO500+ battery for electrifying off-road mobile machines. The solution is based on the company’s modular battery platform. The new battery is optimal, especially for power-intensive heavy-duty applications, including mining, construction, material handling, and agricultural and forestry machinery.

ePRO500+ offers flexibility in capacity and voltage to meet the strictest demands of hybrid and full electric machines. The Proventia ePRO500+ battery system offers power or energy-specific variants with nominal voltage from 48V up to 800V. The battery system is based on the stable and safe lithium titanate oxide (LTO) technology, which has a superior lifetime in cyclic use. LTO technology with a wide operating temperature window from -30 to +60 C° is an essential advantage in harsh environments of heavy equipment.

According to Proventia’s Product Manager Jari Granath, ePRO500+ is a perfect match for machinery when high-power and utmost operational safety matters. High C rates of LTO batteries mean fast charging. Robust mechanical construction with the most durable packaging lasts in rough conditions.

In hybrid applications, ePRO500+ can be used to cover the peak power and the combustion engine can be run at optimal efficiency – leading to lower fuel consumption and CO2 emissions. In full-electric applications ePRO500 + enables zero-emission operation. For the machine owner, batteries reduce the total cost of ownership.

In the development of batteries, Proventia uses its expertise in EV battery development and testing and over 25 years of experience in NRMM powertrains. The company has its own R&D center with versatile battery simulation and virtual validation capabilities. In addition, Proventia has an in-house engine and battery testing center, which also enables hybrid testing.

Jari Granath opens up Proventia’s cooperation with machine manufacturers: “Machine’s electric systems and its controls are quite complex. There are power transmissions and a vast amount of hydraulics with electric motors and other subsystems, for instance. We create virtual simulation models describing the operation of our batteries. These models our customers can utilize as part of the machine’s virtual simulation model. This helps customers confirm that the battery delivers the optimized amount of energy and is compatible with program control logic and other electric systems. At the end of the day, a virtual simulation model saves a lot of time and money in machine design.“