Komatsu has announced it will unveil its 20-tonne class all-electric hydraulic excavator – the PC210E – for the first time at Bauma 2022 in Munich next week (24-30 October 2022), with the machine scheduled to be introduced to the Japanese and European markets in the 2023 financial year.

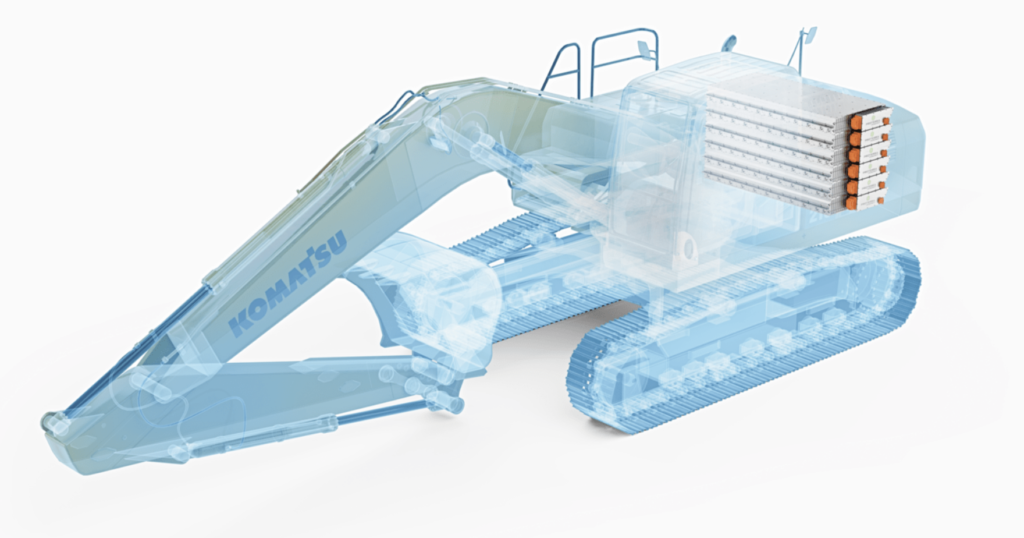

This PC210E optimizes the entire body control system by capitalizing on Komatsu’s proprietary coordinating technology. It specifically integrates lithium-ion battery technology from US-based Proterra, which has a proven track record for use in heavy-duty and commercial vehicles deployed in various fields around the world, with Komatsu’s components, such as the hydraulic pump, controller, and electric motor for work equipment operation.

In addition, Komatsu has developed a robust cage structure to provide additional protection onboard the vehicle for its battery packs. As a result, Komatsu has achieved digging performance and durability equivalent to those of engine-driven hydraulic excavators. In addition, the high energy onboard the excavator’s Proterra battery system enables operation for up to 8 hours when fully charged (operation of 5 to 9 hours was achieved in proof-of-concept tests, depending on the workload conditions).

The electric power makes it possible to work comfortably in various work environments without worrying about noise and exhaust emissions, and is expected to be used for work in urban areas and nighttime construction work, etc. The zero engine vibration will also help reduce operator fatigue.

As global awareness of climate change accelerates, Komatsu has declared to achieve carbon neutrality by 2050 with the aim of realizing a sustainable society. In collaboration with its partners, Komatsu is developing electric construction equipment to achieve zero exhaust gas emissions and a significant reduction in noise emissions with the vision of developing safe, highly productive, smart and clean workplaces of the future.

EV battery power

Since January 2021, Proterra and Komatsu have been jointly developing electric medium-sized hydraulic excavators, and have been conducting proof-of-concept tests on advance research machines at customers’ construction sites.

The collaboration represents Proterra’s entry into the off-road vehicle market and the company’s first Proterra Powered battery-electric construction equipment. The Proterra battery system powering the electric excavator will feature high energy density and fast-charging technology.

Engineered and manufactured in the US, Proterra battery packs have a customizable design to fit within a variety of vehicles. The packaging flexibility of Proterra’s battery platform will further enable the optimal placement of the batteries within the middle class excavator and replace the need for a normal counterweight used to balance the excavator’s hydraulic arm movements

I am excited about the collaboration with Proterra, by which Komatsu will drive the electrification of construction equipment,” said Seiichi Fuchita, president, development, Komatsu Ltd.

Proterra Powered leverages Proterra’s electric vehicle technology and expertise to help commercial vehicle manufacturers electrify their vehicles. Proterra battery systems are utilized by world-class OEMs to introduce 100% battery-electric vehicles, including electric school buses, coach buses, delivery vans, and low-floor cutaway shuttle buses. To date, Proterra Powered has helped world-class OEMs introduce 100% battery-electric vehicles and equipment that are powered by Proterra electric vehicle technology.