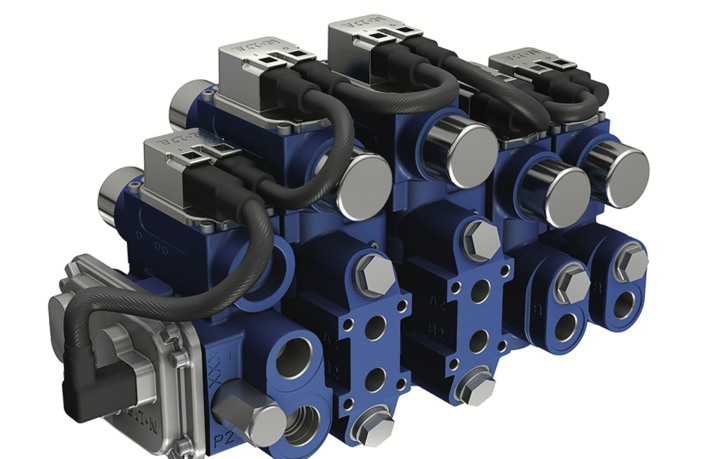

CMA mobile valves take machine performance and precision to the next level in just about any advanced control application thanks to the integration of sophisticated electronics, software and programmability.

Now, following the development of optional CMT sections, it is possible to achieve even more. With the ability to control two low-level functions simultaneously, design engineers can create optimised valve systems that are both smaller and more cost-effective.

While CMA sections are perfect for services demanding precise control, such as booms and drilling rigs, the new CMT sections are ideal for machine functions like buckets and clamping, which only require accurate meter-in flow control. Able to meet either demand in one valve solution, designers can ensure that machines have the best of both worlds.

• More design freedom: By merging the next-generation performance of CMA sections with CMT sections, valve solutions can be created that match the machine’s exact requirements.

• Optimised valve systems: One CMT section is capable of controlling two separate machine functions independently. This capability can reduce the total number of sections needed in a valve bank by up to 50%, minimising valve size, weight and overall cost.

• Flexible configuration: Providing highly accurate meter-in flow control, CMT sections are software-configurable and feature CAN communication, on-board sensors, digital flow-sharing and electronic load-sensing.

Interested? contact us at: https://www.eaton.com/gb/cmt

ADVERTISEMENT FEATURE