It’s getting serious; climate change is now undeniable. If industry is to continue to make products and provide secure jobs, the efficiency of manufacturing processes must be massively improved. With new system designs based on its AX technology, Bucher Hydraulics is proving how this can be achieved with hydraulics in drive technology.

Several political initiatives at national and European level are aimed at increasing efficiency in the interests of climate protection. Industry must also play its part here. Among other things, conventional drives should be replaced by highly efficient electrically powered solutions. The entire system is considered and no longer just the individual components. Networked drives should allow for a management system that uses energy as sparingly as possible.

In the past, energy-efficient solutions often failed because the initial price was too high, and the cost of energy as well as the cost of buying CO2 emissions credits were still too low. The current climate problems and discussions are changing this situation. Electromechanical drives with lower energy consumption often come up against technological limits, however, especially when high forces are required in a small space.

Hydraulics catches up

Hydraulic cylinders are the clearly obvious choice for generating linear movements with high forces. One disadvantage: in conventional systems, the movement is controlled by valves that suffer high throttling losses and therefore high energy losses. The energy efficiency is further limited by the hydraulic power units: in large systems these usually have a centralized design, and the energy then has to be distributed over long distances.

When building machines, however, the established systems cannot be beaten on price as far as the initial costs are concerned, which is why they are still very significant in mechanical and plant engineering. One point that is usually not considered: over the course of their service life, they result in energy costs so high that these can far exceed the original investment.

For some years now, manufacturers of energy-saving electromechanical drives have been trying to displace hydraulic drives from linear movements and substitute their own drives instead. So far, however, direct electric drives without any gear unit have only been available in isolated cases and with limited performance. As appealing as a direct drive may be to the designer, electric drives without any gearing are inherently very large, because many applications require high forces even at low speeds.

Basically, each electromechanical drive is driven by its own electric motor. In traditional hydraulic systems, on the other hand, an electric motor plus hydraulic pump drives several cylinders via control valves. This explains why electromechanical drive technology requires a considerably higher investment. And for high forces, which hydraulic cylinders provide very easily, mechanical linear drives are much more complex and heavy.

Highly efficient decentralized hydraulic linear drives

The German government’s energy efficiency strategy calls for highly efficient decentralized drives that are, however, networked and function as overall systems. This requires new system approaches and subsystems. Using this principle, throttling losses from the control valves can be completely prevented if each individual hydraulic cylinder is driven by its own electric motor and pump. This eliminates the root cause of the low efficiency of traditional hydraulics.

One other major advantage compared with the rigid arrangement of electric motor, gear unit and spindle of an electromechanical linear drive: the components of the hydraulic linear drive can be arranged flexibly in machines and systems. This means that the compact dimensions of a hydraulic cylinder can be fully exploited. The electric motor and pump can be mounted in a suitable nearby location. In addition, many other features of conventional hydraulics such as overload protection, heat dissipation, damping or emergency stop functions can be easily incorporated.

The critical component in applications of this type is often the pump, because its reliability is not optimal at every operating point. This is especially true with high forces and low speeds, or when reversing. When conventional hydraulic pumps were developed 50 years ago the designers did not have these particular operating modes in mind, but the pumps are still being used in these modes today, although with certain restrictions. This is why, in a linear drive subsystem, conventional hydraulic pumps generate the highest power loss.

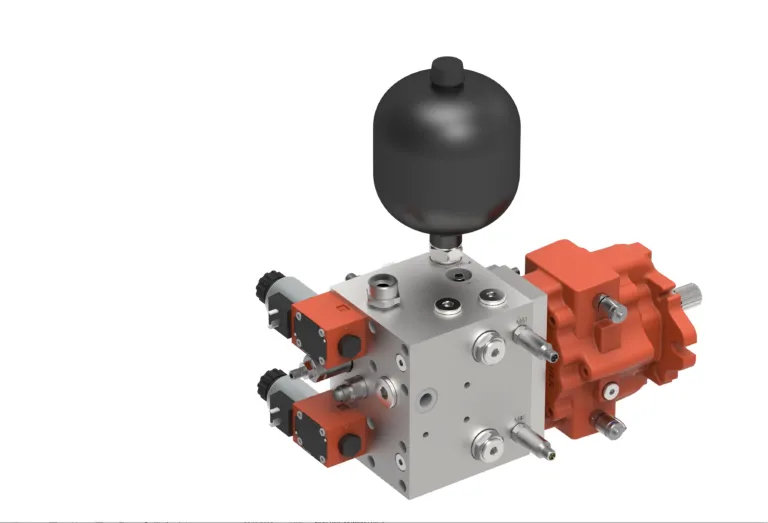

Using the innovative AX pumps, Bucher Hydraulics has now developed highly efficient, decentralized linear drives HELAX (hydraulic electric linear axis based on AX technology) specifically for these purposes. Using no throttling valves at all, they work with speed-controlled servo motors and AX pumps in a closed circuit. Their performance is absolutely comparable with, or even better than mechanical linear drives. The well-known advantages of the hydraulic cylinder in the areas of power, speed, robustness and reliability are fully retained.

Ideal for variable speeds

The AX pump is ideal for variable speed applications: with 24 pistons, it features very low pulsation levels, and it can be operated without problem and with the highest reliability in all four quadrants. It can be used over the whole performance range of the electric linear drive.

Conventional pumps have a minimum speed that must be strictly observed, but this restriction no longer exists with AX pumps. With a high efficiency of up to 94 percent, the power loss of the AX is at the same level as that of electric motors and gear units. Last but not least, they have reassuringly low noise levels.

Conventional hydraulic systems consist of numerous components that need to be adjusted and optimized for the particular application. This requires specialist hydraulic knowledge. Because there is no apprenticeship for hydraulic technicians, hydraulics knowledge is less common than knowledge of electrical technology.

Thanks to the on-board electronics, in conjunction with specific software, the hydraulic linear drive can be commissioned with a knowledge of electrical drive technology only, and without any special hydraulics know-how. The motion control signals are transmitted via CAN bus, for example: the software then converts the signals into the required movement. Users do not have to get involved with the detailed characteristics of the hydraulic system: they can concentrate fully on the function of their application. The hydraulic linear drive can therefore be integrated into the system like any electric drive.

High positioning accuracy and force

The overall efficiency of the drive system, consisting of inverter, servomotor, AX pump and cylinder, reaches up to 82 percent. When recovering potential energy from lowering and braking processes, an efficiency of as much as 84 percent is possible.

Tests also demonstrate a very high positioning accuracy, even with large forces. To prove the system’s high performance, the experts at Bucher Hydraulics developed a control system for an inverse pendulum assembly weighing 1.2 tonnes. The hydraulic subsystem operates continuously without any cooler.

Networking made easy

The electrical servo motor of the hydraulic linear drive is connected to the DC grid. This provides for energy networking: energy fed back from another drive can be used immediately and directly. Of course, it can also be temporarily stored in energy storage systems such as batteries. The energy storage units can provide peak power for short periods without burdening the power supply with high and costly spikes in the demand for current.

With regard to Industry 4.0 concepts in the areas of digitalization and networking, the system can be monitored with just a few sensors and the drive controller data that is already available. This data opens the door to efficiency-boosting energy management, condition monitoring and, last but not least, predictive maintenance. This means that it meets far more than just the current requirements for high energy efficiency.

Questions to Dierk Peitsmeyer, product portfolio manager at Bucher Hydraulics

Why do we need our hydraulics to be more efficient?

In December 2019, the German government adopted the Energy Efficiency Strategy 2050, and the EU is planning something similar with the ‘Green Deal’ initiative. It has been recognized that the CO2 reduction targets cannot be achieved without further legislative measures and subsidies. By 2030, the German government wants to reduce primary energy consumption by 30 percent compared with 2008. The EU Parliament has now even decided on 60% compared with 1990. Germany also needs to make much faster progress if it is to meet the annual savings commitments for 2020-2030 set out in Article 7 of the EU Energy Efficiency Directive. The ‘Efficiency First’ principle is intended to help in this respect.

Conventional hydraulic systems incur high energy costs that often even exceed the original investment amount. Why do businesses barely react to this?

The hydraulics industry has actually done its homework and has now developed many efficient, energy-saving solutions. But these solutions are not achievable for the price of a traditional solution. Because the energy costs are only incurred while the plants are actually being operated, they go to a different cost center than the one used for the initial costs when the plant is purchased. This is why the purchasing department usually still decides on the basis of the pure ‘up front’ price of the machine and does not consider the overall costs during operation, the Total Cost of Ownership (TCO).

How can the AX technology from Bucher Hydraulics contribute to achieving the CO2 targets?

Decentralized linear drives can provide the ideal help in meeting the requirements of the Energy Efficiency Strategy 2050. The AX pumps guarantee reliable operation with high performance and low power loss, while at the same time all of the well-known advantages of the hydraulic cylinder are retained. We set out to demonstrate the performance by building a world-first inverse pendulum rig with an active weight of 1.2 tonnes. The hydraulics swing the pendulum to top dead center and then balance it there smoothly. This means that manufacturers of machines that require high forces have at their disposal an excellent subsystem for solving their linear drive tasks. By the way, 2030 will be here sooner than we think!

The HELAX benefits at a glance

- Hydraulic linear drives with AX pumps provide dynamic and precise control even where large masses and high forces are involved;

- Performance is comparable with or better than electromechanical linear drives;

- Quiet, and low vibration levels;

- Dynamic, precise and direct;

- Highly efficient both as motor and as generator;

- Low wear and low maintenance, rugged and reliable, just like a conventional hydraulic drive;

- Lighter and more compact than mechanical solutions;

- Flexible component arrangement (only rigid arrangements are possible with mechanical systems);

- Simple installation and commissioning;

- No specialist hydraulic knowledge required;

- For parametrization, a knowledge of electrical drive technology is sufficient;

- With energy recovery, high system efficiency of up to 84 percent: comparable with or higher than electromechanical systems.