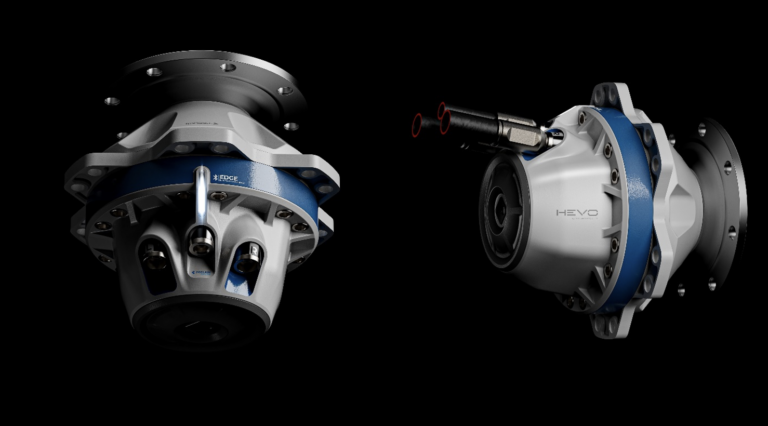

Poclain, with four generations of hydraulic radial motors, stands as a leader in such technology. To address the challenges posed by the urgent need for energy efficiency, it has embarked on a revolutionary journey known as the HEVO programme.

Motor with lower flow requirements

Enhancing the energy performance of hydraulic systems is the key to reducing energy consumption and CO2 emissions. The most effective path to achieving this goal is by reducing the demand for hydraulic flow, thus minimising friction, heat generation, and energy losses.

The most effective path to achieving this goal is by reducing the demand for hydraulic flow, thus minimising friction, heat generation, and energy losses.

Transforming hydraulics

Launched in 2021, Poclain’s HEVO programme is a testament to what can be accomplished. This programme represents a significant advancement in off-road machinery, offering a substantial reduction in energy consumption and an increase in power output of up to 30%.

By breaking free from the constraints of conventional design, the HEVO hydraulic programme proves that energy efficiency and enhanced productivity can coexist harmoniously.

Precise sizing of the transmission

Facing major energy and environmental challenges, one of the keys lies in harnessing energy efficiently at every stage of a machine’s life. Poclain, with its unwavering commitment to a sustainable future, has devised a dynamic strategy centered around efficient transmission.

A partner of Poclain since June 2022, Samsys specialises in fleet management telemetry. Their combined expertise enables OEMs to access the full spectrum of vehicle monitoring, including duty cycle, diagnostics and usage.

ABOVE: Poclain and Samsys’s joint expertise enables OEMs to access the full spectrum of vehicle monitoring, including duty cycle, diagnostics and usage

By measuring a machine’s performance, Samsys and Poclain’s solutions help determine if the vehicle and its components are the right fit for a particular job. They also provide insights for new developments, machine daily operation and support for maintenance and servicing.

Poclain dives deep into component optimisation, offering an array of efficient hydraulic motors and pumps. Poclain’s relentless pursuit of innovation in its hydraulic core technology means that it is constantly working on breakthrough technologies that enable even greater efficiency.

With the growing emphasis on electrification, Poclain developed a range of electric components, capitalising on the expertise of its newly acquired power inverter company, EMSISO.

ABOVE: Poclain’s recently acquired power inverter company, EMSISO, enabling it to develop a new range of electric components

Poclain’s groundbreaking shift from ‘power-based transmission sizing’ to the ‘energy-based transmission sizing’ significantly improves CO2 emission levels and grants a better autonomy to electro-hydraulic or full electric machines.

Even at the end of a product’s life, energy efficiency remains a priority. Its new remanufacturing program plays a pivotal role in achieving sustainability. Real-time monitoring of components allows for proactive maintenance planning and evaluation of remaining useful life. As a result, customers can operate smoothly, upgrading critical components when needed and continuing essential operations with remanufactured motors that are as good as new.

ABOVE: Poclain’s new remanufacturing programme plays a pivotal role in achieving sustainability

Poclain adopts a holistic approach, dedicated to fostering an energy-optimised industry that effectively addresses the challenge of reducing CO2 emissions.

For those who would like to know more about Poclain’s HEVO programme, the company invites them to attend dedicated presentations at its Agritechnica booth (HALL 16 – B16) : Timetable HERE