Yanmar is moving into the high-power industrial diesel engine market with the launch of two new Stage V engines that produce up to 155kW, it announced at Intermat Paris this week (April 23-28).

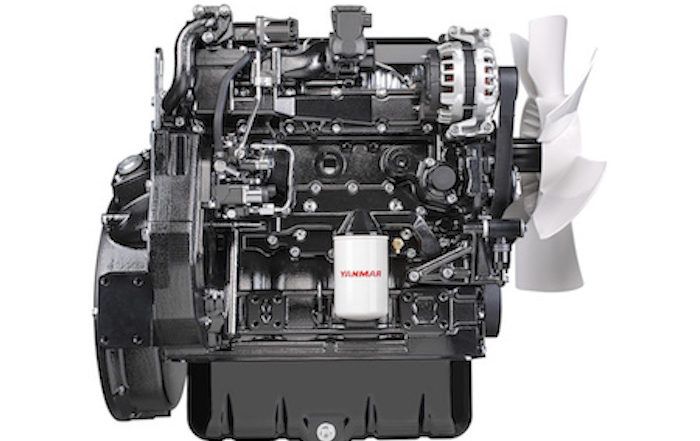

The new 4TN101 (above) and 4TN107 engines (below), which were on display on the Yanmar stand, are the result of the company’s experience in developing cutting-edge diesel engine technology, and show the company’s commitment to producing the very best high-power, fuel-efficient diesel engines that the market demands.

The new engines achieve fuel consumption reductions of approximately 10% compared to a similar-sized engine with the same output. The improvement in fuel efficiency results in longer operation times and contributes to significant financial savings throughout the life-cycle of the engine.

Both engines deliver superior torque to meet the requirements of a wide variety of industrial fields, including construction, agriculture and material-handling. Furthermore, the 4TN107 with a two-stage turbocharger can achieve a maximum torque of 805Nm.

The compact profile of the engines takes into account the needs of vehicle manufacturers, improving installation characteristics. Yanmar’s proprietary exhaust-gas reduction technology results in a more compact exhaust-gas after-treatment system markedly improving the outward visibility and the comfort level for machine operators.

Yanmar’s engines utilize a Diesel Particulate Filter (DPF) to reduce particulate matter (PM) and a Selective Catalytic Reduction (SCR※5) system to reduce harmful emissions. These technologies, which have been refined from Yanmar’es experience developing smaller engines, allow the 4TN101 and 4TN107 to comply with EU Stage V regulations.

The 4TN101 and 4TN107 produce outputs ranging from 55 to 105 kW and 90 to 155kW, meaning the engines can be used in a wide range of machinery with various output needs.