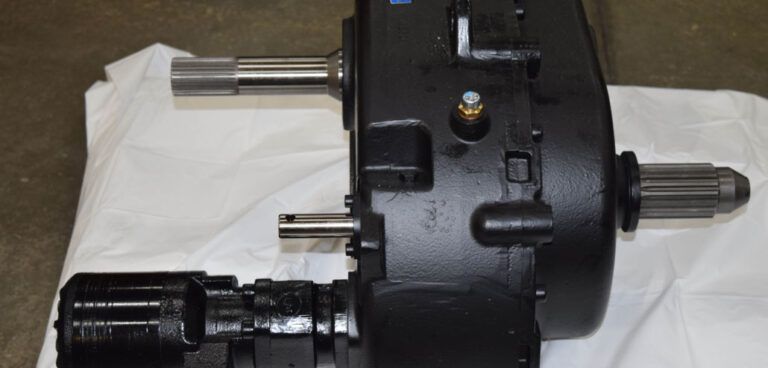

Tribine Harvester has announced the launch of a custom rotor gearbox that will be standard in all of its vehicles. The proprietary reversible rotor gearbox was developed in collaboration with Italian firms Bondioli and Pavesi.

The new 2-speed system provides hydraulic assist to start Tribine’s 38in rotor but also provides the ability to reverse the rotation should it slug.

Greg Terjesen, Tribine’s vice president of sales and marketing, said, “This new reversing gearbox is extremely robust and the most heavy-duty gearbox in the industry today.

“By developing proprietary components like this gearbox, it keeps our company at the forefront of technology, as we continue to listen to the voice of the market. By continuing to develop proprietary components we are further reinforcing our long-term commitment to our customers, and the combine market.”

For all vehicles

All machines featured at future trade shows will be equipped with this new gearbox design, while Tribine Harvester is in the process of retrofitting all machines. Powered by a powerful hydraulic motor, this new design can be controlled directly from the machine’s cab.

Tribine Harvester moved into its Newton, Kansas, production facility in February 2016, with the first production unit rolling off final assembly in July of 2016. Designed and built in the USA, the Tribine is the first fundamentally new ‘combine’ to be introduced to the market since the 1940s.

Read a case study about the vehicle in the September/October issue of iVT.