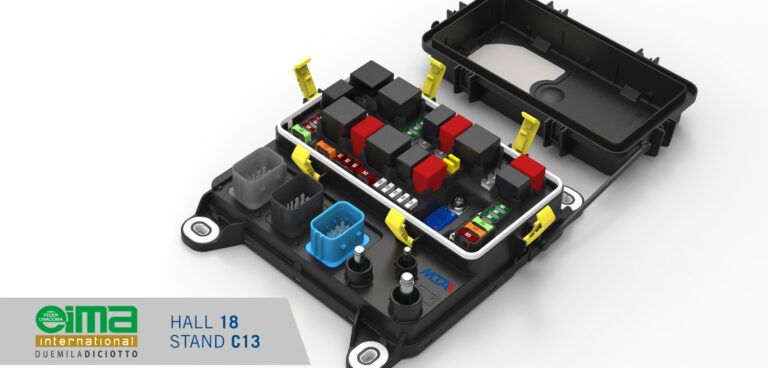

MTA has recently developed MEC 97, a modular electrical center for the distribution of power and the protection of major electrical utilities in agriculture, construction, heavy-duty and off-road applications.

MEC 97 is a plug-and-play product produced with the PCB (printed circuit board) logic and with press-fit assembly, an innovative solderless connection technology where the contact between the press-fit pin and the wall of the hole is gas-tight, ensuring optimal electrical contacts even in the presence of strong vibrations.

MEC 97 allows to integrate all the functions in one piece, thus eliminating the need of different modules and associated wirings. The vehicle is therefore lightened from costly and heavy modules and cables, the wiring layout is simplified and the assembly time reduced.

Customizable is better

MEC 97 is evidence of MTA’s aim of offering off-the-shelf products that can subsequently be customized by the OEM for the specific application they are intended for. In fact, it comes with a basic configuration, where customers can assemble a wide range of relays and fuses depending on the electrical layout.

Relays and fuses are all plug-in or bolted components and not welded ones, thus allowing an easy replacement in case of damage. Upon request, for mass production, MEC 97 can however be customized: case and cover of the unit remain standard for all configurations, while the fuses/relays frame, which is a separated component of the MEC 97, together with the PCB, can be configured, making the unit a highly versatile product.

In addition, the external case of MEC 97 can be tailored: the off-the shelf product comes with two customizable studs for coupling both with ring or “’fast connection’ terminals and four connectors, but the number of studs and connectors can vary depending on customer’s needs.

Mechanical highlights

MEC 97 comes equipped with an anti-vibration system integrated inside the fixing points, to assure high mechanical and electrical performances in severe applications and to stop OE manufacturers needing to mount silent blocks.

The unit also features: a Gore-Tex vent that provides a barrier against water and dust and allows the free circulation of air in the unit, avoiding the formation of moisture; an overmolded sealing gasket; and six latches which preload the cover against the seal and close the MEC 97.

These characteristics ensure an IP69k protection degree for the high demanding environments where the targeted machines operate. Moreover, the cover is tethered to the body to ensure it won’t be displaced during assembly or maintenance.

MEC 97 can be fitted in any compartment of the vehicle, including the engine one, where it can be positioned horizontally, vertically or inclined, thereby taking maximum advantage of the available space.

MEC 97 is compatible both with 12V and 24V electrical architectures and, upon request, can host a module to convert CANbus messages into digital outputs.