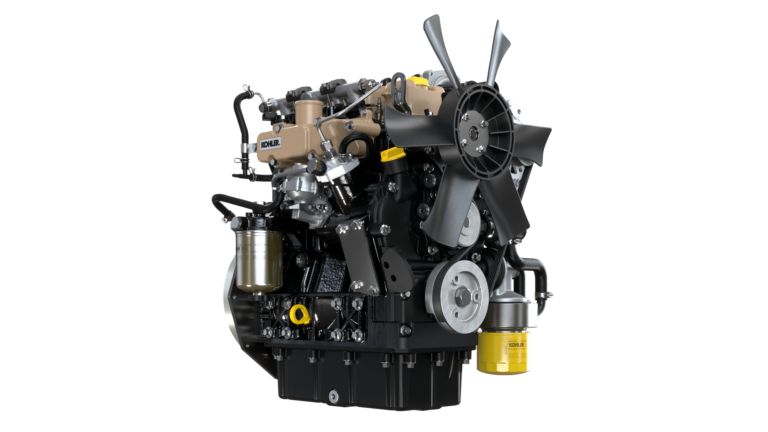

Kohler Engines has introduced its latest investment, the KSD Series – also known as Kohler Small Displacement – a new engine family that represents the hard work of its global team. The product has been conceived and designed with a global approach suitable for all regions, compliant with all standards worldwide and compatible with all kinds of machines.

KSD engines can be easily integrated with the more complex electronic systems of ever evolving machines, allow customised settings for any duty cycle and the ability to exchange data with few physical connections. They are also versatile and can be integrated without modifing or redeveloping the machine.

Three model solution

The KSD Series is currently made of three engine models, with others to come in the next few years:

KSD 1403NA (naturally aspirated)

KSD 1403TC (turbocharged)

KSD 1403TCA (turbocharged with aftercooler)

The performance include high low-end torque: 95 Nm @ 1000 rpm, peak torque at low speed: 20 Nm @ 1400 rpm and peak power: 18.4 W @ 1800 rpm.

The wide variety of emission standards has introduced a new level of complexity to the engines business. Kohler has taken this complexity and transformed it into an opportunity. It happened with the KDI Series, and it’s happening with the new product: a new engine below 19kW that complies with all global emissions standards and fuels. And multi-fuel solutions will enrich the offering: diesel, gasoline and propane.

The versatility of KSD engines goes beyond performance, with the ability to easily fit into existing telematic solutions. The engines are electronically controlled, while being as simple to use as mechanical engines. The fuel system then allows precise fuel metering and excellent load response, resulting in time saving and increased productivity. Durable components make the engine ready for any heavy duty applications.

Dual side service and full flexibility for fan position make the engine able to fit a wide range of machines. The integration between the engine and the machine is enhanced: better response, drive by wire, speed control, auto stop, pedal map setting, and fan speed control. The electronic controls allow the engine to maintain high performance at high altitude. Furthermore, these features allow you to optimize fuel consumption by controlling the hydraulics of the machine and the engine load and speed.

KSD engines allow for prognostic, diagnostic, geolocation, remote monitoring and switchability for genset application, and offer a service interval of up to 500 hours, for both oil and fuel filters.

The range of possible applications is as wide as your imagination can perceive, because the KSD is ready to fit machines of the present and future: generators in the power sector, tractors in agriculture, excavators and loaders in construction, and forklifts in logistics, as well as compressors, dumpers, mowers, even refrigeration.

Combustion system

The injection system is the heart of every engine. The innovative technology brought on by the KSD is its architecture: it features a state-of-the-art indirect injection system but has the specific electronic management typical of direct injection engines. Major benefits are:

– the engine performance is maximized in every operating condition and environment: at sea level as well as at high altitudes

– outstanding engine response, as the system offers a very limited speed droop as well as isochronous control if required, like in bigger displacement common-rail engines;

– the amazing low-end torque allows the operator to run his piece of equipment at lower rpm to save fuel;

– the electronic injection system results in no visible black smoke;

– operator comfort is a main priority; noise and vibrations are minimized as a result of a carefully conducted NVH analysis.

Cost of ownership

KSD engines provide extended oil intervals. In fact, the focus on clean combustion drives low oil consumption and avoids oil dilution as well as heavy soot oil contamination. This is thanks to the unique piston ring design, a dedicated in-house honing machining process, and a specific crankcase ventilation system with a cutting-edge design. In addition, KSD engines offer a 2000-hour heavy duty environment Poly-V belt solution. Service intervals have been extended more than ever. Again, complexity becomes simplicity.