As a complete power solutions provider for OEMs, John Deere Power Systems (JDPS) has expanded its lineup of engine and electric drivetrain solutions.

“We’re continually focused on providing our customers with power solutions that fit their applications’ needs. That’s why we’re growing our power range and optimising our latest technologies,” said David Hoffman, director of worldwide marketing, sales and customer support at John Deere Power Systems.

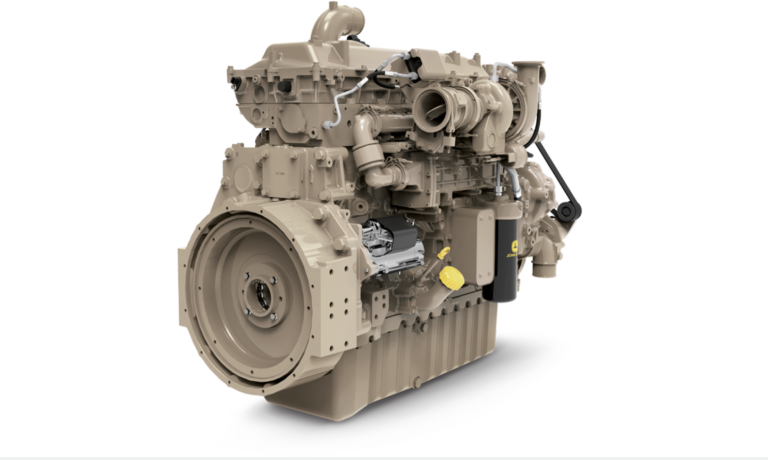

13.6L engine puts customer needs first

The 13.6L engine was built with a clean-sheet design, offering new levels of performance, serviceability and integration — all key characteristics for OEM customers. This design process was driven specifically by customer requirements.

The team considered the top customer needs and created a list of design requirements to meet those objectives. “We leveraged and optimised our proven technologies developed over the years to best address market and customer needs in heavy-duty applications. This ensured the final product would deliver increased performance and overall value to our OEM customers and end users,” said Hoffman.

Beyond meeting performance needs, John Deere is offering hardware solutions to meet market demands with the 13.6L engine — including a no-DPF solution for Final Tier 4 variable and constant speed markets. This adds to the no-DPF variable speed engines offered by John Deere.

New 18.0L engine expands lineup to meet market needs

Building on the 13.6L engine design, John Deere has introduced a new 18.0L engine, which offers maximum power over 650 kW (870 hp). It was also designed with flexibility, serviceability and durability in mind.

This performance engine is equipped with John Deere engine controls, a high-pressure common-rail fuel system and series turbochargers and utilizes cooled EGR. The model-based controls enable advanced prognostics capabilities and improved transient response. A rear gear train reduces noise as well as torsional and crank stress. The top 20 service and repairs for larger John Deere engines were also taken into consideration when designing the engine to ensure ease of serviceability.

“We utilised a streamlined engine design process to expand our power range. Advanced modeling allowed us to define and optimise engine subsystems to achieve our performance requirements and to deliver on our customers’ growing horsepower needs,” said Hoffman.

The new 18.0L engine will be manufactured at the John Deere Engine Works plant in Waterloo, Iowa. Production of the 18.0L is planned to begin in 2022.

4.5L options for a range of applications

The John Deere 4.5L engine can be applied to products requiring power levels from 55 to 129 kW (74 to 173 hp) in many different configurations based on market requirements. This includes single and series turbo performance engines covering 63 to 129 kW (85 to 173 hp) in configurations with and without a DPF for both variable and constant speed markets.

Additionally, no-EGR engines are available at 55 kW and constant speed ratings to satisfy the 80 kVA and 100 kVA markets. John Deere is expanding its no-EGR offering to include variable speed ratings with and without a DPF, as well as constant speed ratings for the no-DPF market.

“We understand that our customers’ needs vary, and we continue to develop multiple options for our 4.5L engine platform that are optimised for their specific application needs,” said Hoffman.

New electric drivetrain components available in North American

The latest iteration of the OEM electric drivetrain components from John Deere are tough enough for the construction industry. John Deere leveraged 1.5 million hours of electrification experience in construction equipment to deliver on the characteristics most important to its OEM customers: durability, scalability and flexibility.

“We were among the first to introduce electric drive technology in construction equipment with our 644K and 944K Hybrid Wheel Loaders. With this experience, we’ve developed an effective, proven solution in an emerging market with the durability our customers have come to expect from John Deere,” said Darren Almond, strategic marketing lead, electrification, John Deere Power Systems.

The portfolio is modular for ease of OEM integration. This flexibility minimises the need to re-engineer vehicle design to begin testing and implementing electrification solutions. “We’ve identified key electric drivetrain components that will integrate into existing space claims, further streamlining the transition to electrification for OEMs,” said Almond.