Finnish exhaust system supplier Finse Ltd recently introduced a new thermal insulation product, FTC (Finse Thermal Cell), which is manufactured in-house from start to finish and can be designed and tailored for each individual machine.

Thermal insulation is a vital component of heavy machinery exhaust systems in order to maintain the functionality of SCR emissions control systems and ensure a safe working environment for the operator.

“Despite Covid-19, we invested in the manufacturing process of exhaust pipe insulation. We have invented a manufacturing method that is unique in the industry and makes it possible to produce sheet metal moulds extremely quickly, flexibly and cost effectively,” says Antti Hyppönen, managing director of Finse.

Finse utilises a semi-automated production line process for exhaust pipe insulation packages. All processes are done in-house and not subcontracted in order to ensure the highest quality, speed and flexibility.

The outer layer of Finse Thermal Cell is typically made from moulded stainless steel sheet metal with a thickness of 0.15–0.20 mm that complies with the EN 1.4016 and AISI 430 standards. The insulation material is usually 6–50 mm SuperWool or 3–15 mm IsoGlass.

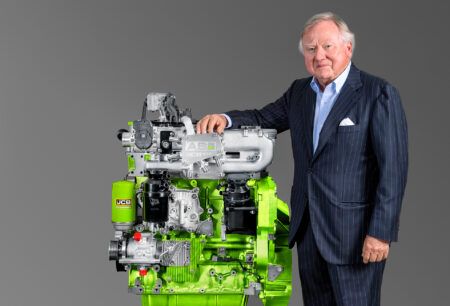

Family-owned flexibility

Finse Ltd is a family-owned metalworking company that specialises in heavy vehicle pipe components, including exhaust pipe systems, water and oil pipes, and tubular protection. Finse products are used by tractors, forestry harvesters, generators, mining machinery and even London’s famous red buses.

“We are a family business whose owners are actively involved in the company´s everyday operations. This means that we can make decisions fast and on the spot. Finse is small enough to be flexible yet big enough to ensure that no function is dependent on one person alone,” says Managing Director Antti Hyppönen.

Finse’s international machinery clients include AGCO, Proventia, John Deere, T Max and Sandvik. The quality of the company’s operations is backed up by ISO 9001 quality certification, ISO 3834-2 welding certification, ISO 14001 environmental certification and audits by OEM clients.

“Thanks to our specialisation and sharp focus, we are able to help clients design and plan the production of tailored pipe components. Our experience allows us to advise our clients on the most suitable, cost-effective and high-quality production methods for their products,” says Hyppönen.

Finse has earned a reputation among OEM machinery manufacturers for its ability to make the tightest bends for thin stainless steel tubes. Finse uses state-of-the-art 2D and 3D laser cutting machines to form metal, and welding 1- to 3-millimetre stainless steel sheets and pipes is no problem.