Hydrogen ICE general manager, Jim Nebergall, used this week’s Utility Expo in Kentucky, USA, to talk about hydrogen in construction at the Diesel Progress Summit panel discussion.

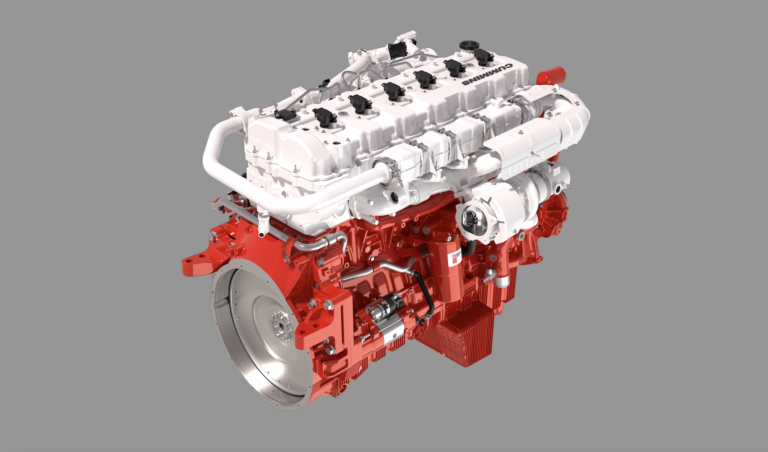

This new platform works with hydrogen, biogas and advanced diesel engines and offers OEMs the opportunity to accelerate the decarbonisation of off-highway applications. It has a significant increase in power density with a more compact installation envelope enabling OEMs to increase machine capability and productivity with no impact on running cost.

“Change is hard,” said Nebergall. “Transitioning the off highway and commercial vehicle markets away from carbon-based fuel is very challenging. There isn’t a single solution that will accomplish this transition. The industry needs multiple solutions that enable carbon reductions today, tomorrow, and in the future. Hydrogen engines can deliver on these needs and will play an instrumental role in the industries decarbonization journey. This versatile zero-carbon fueled technology integrates into existing equipment while providing diesel like performance and maintenance practices. Hydrogen engines are the least disruptive technology for the commercial markets.”

The fuel-agnostic architecture of the 15-litre next generation engine utilizes a common base engine with cylinder heads and fuel systems specifically tailored for hydrogen, natural gas, diesel and biofuels including HVO.

The 15-liter hydrogen engine will be available with ratings from 400-to-530 hp and a peak torque of 2600 Nm. For applications powered by renewable biogas, this engine will offer ratings from 400-to-510 hp with a peak torque of 2500 Nm available. The advanced diesel version features will offer a broad power range of 450-to-650 hp, with an impressive 3200 Nm peak torque.