Bonfiglioli is expanding its electromobility business with the construction of an environmentally friendly facility.

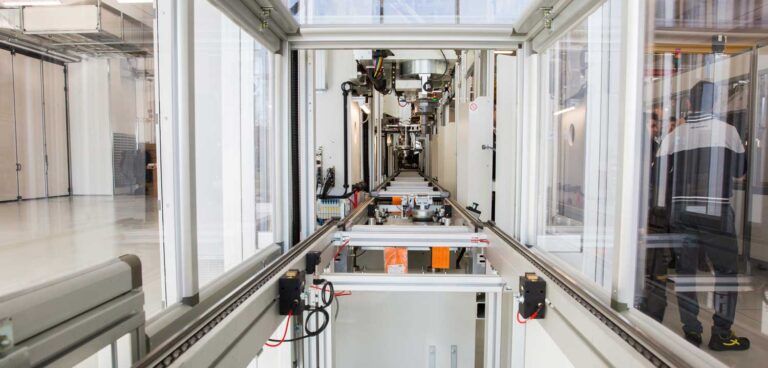

Built within 12 months, the sustainable new unit in Forlì, Italy, is dedicated entirely to the production of electric axles for powertrains and wheel drives of various sizes. Thanks to its energy saving and energy generating measures, the 10,000m² (107,640ft²) production line is an A2 energy class building, lit by LED lighting with a PV rooftop and a compressor heat recovery system. The measures add up to a yearly saving of approximately 1MWh.

Flexibility was key

Flexibility was one of the main criteria for the new assembly line, resulting in the capability to manage 25,000 products per year, from 70kg to 1,200kg, with reduced machine setup times.

“This new and innovative unit looks to the future and consolidates one of our main strategic pillars – the development of electromobility solutions – by leveraging the existing decade-old competence center we have in Forlì, focused on mobile equipment”, said Fausto Carboni, Bonfiglioli Group CEO.

Marco Cesari, Bonfiglioli mobility and wind industries business unit general manager, added, “This expansion gives us the opportunity to better support our customers with innovative solutions for electrical and hybrid industrial and commercial vehicles. We decided to implement the best of Industry 4.0 technology, to create flexible processes, enhancing quality and productivity standards.”

The building is completely integrated into the existing plant, which already produces approximately 300,000 products per year.

Interested in electric and hybrid technology? Check out the Electric & Hybrid Industrial Vehicle Technology Conference, which takes place during iVT Expo. Both the conference and iVT Expo take place on February 13-14 in Cologne, Germany.