Heavy equipment doesn’t work alone and interoperability between brands of equipment has become more critical. As industrial machinery becomes part of connected networks with command centers and other equipment units, system architectures are incorporating CAN with Ethernet to meet the growing data networking requirements.

Controller Area Network (CAN) systems have been used in industrial machinery applications since the 1990s as part of proprietary manufacturer equipment solutions. Interoperability solutions took shape in the 2000s when the global agriculture industry united behind the work of AEF-the Agriculture Electronics Foundation to develop ISO 11783, a control and communications data network protocol similar to USB found on commercial electronics. This new standard is known as ISOBUS. CAN protocols serve the agriculture, forestry, and off-highway industries, and others that require interconnectivity across heavy machinery units. These functions give operators the ability to realize precision digital applications.

As agriculture and forestry increasingly integrates cameras and sensor-rich monitoring functions into their operations, standardized high-speed connectivity has become a greater need. Today, a high-speed ethernet architecture will allow more data to be shared between the machines. This helps farmers strategically time planting and harvesting; apply fertilizer and insecticide in response to data collected in the field; and manage irrigation systems in tandem with forecasted weather and specific field conditions.

The ability to plug-and-play systems using high-speed ISOBUS will allow for more command and control of prescription, more precise data logging, and detailed display of information. Very soon, these machines will include autonomous capabilities. To achieve these autonomous functions, there is a need to achieve control timing and latency less than 10 microseconds as well as a reliable 1 Gb/s signal integrity for up to 40 M. That will enable the next generation of equipment even greater control. For example, crop planting or spraying systems will use smart optics to control the direction and flow nozzle for each row it passes. In the construction industry, telematics will direct earthmoving machines using shared prescription maps. Additional use cases include obstacle detection, tracking a companion machine and integrating vehicle and remote camera views onto one display.

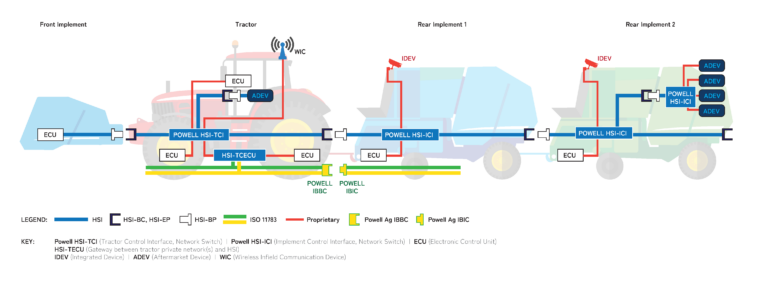

The need to safely create a network architecture to meet these needs led the AEF to begin work on the High-Speed ISOBUS. The choice of Ethernet as the form of this system was guided by its success in the automotive industry and by the development of the Ethernet standard IEEE 802.3bp. The choice of OPEN Alliance software standard OPC UAand other variants allow industrial equipment and applications to communicate together in a secure and reliable way. A standardized Gb Ethernet switch will work as the vehicle control interface and the IEEE802.3bp Type A & B Ethernet connector family will be used for MDI. These single-pair Ethernet (SPE) connectors and shielded cables will connect the switch with any edge sensing and control solutions, creating a true plug and play High Speed Implement BUS (HSI).

An ISO Joint Working Group, across several industries, will standardize how cutting-edge vehicles can achieve secure, high-speed data communication for remote viewing cameras and high-performance command and control. Key hardware for this system is a multipurpose switch that can support the backbone of the architecture paired with single pair ethernet connectors using 20 AWG wires for harnessing linkages.

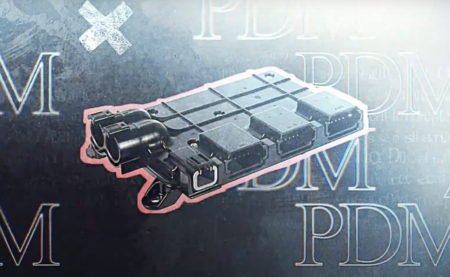

Powell Electronics offers approved connector systems for vehicle cable harnessing and a 1000BASE-T1 Type B Ethernet Switch for this architecture. Connectors and GbE Switch use the latest in IEEE802.3bp technology for Single Pair Ethernet performance standards of 1 Gb/s up to 40M. This enables High-definition data sharing across multiple devices and suitable for many applications. The HSI GbE Switch leverages the use of automotive suppliers with long life roadmaps. No development costs or new tooling requirements are needed. This is a vetted and tested ethernet switch ready to be used on vehicles immediately. The solution has a cost advantage from economies of scale, using common materials and processes within existing volumes of similar manufacturers. Backed by a strong technical understanding and circuit reuse of existing products, Powell Electronics solutions reduce the risk of failure while meeting the new ISO 23870 standards and AEF HSI Guideline requirements.

The Powell High-Speed Implement BUS, Gb Ethernet Switch, is a one-of-a-kind solution for the latest technology used by agricultural machinery and heavy equipment. Powell Agricultural Solutions has continued its legacy from ISO 11783-2 into the new architecture designs and are offering the pictured product for sale. Powell has focused on a harsh environment, sealed, active and passive electronics to support ISOBUS (ISO 11783) and High-Speed Implement BUS applications (ISO 23870 in draft). These products will help our customers to develop their precision applications and technologies.