Curtiss-Wright Industrial division has announced that it will be using its stand at Bauma 2022 to promote its electrification portfolio including the recently-announced traction inverters and its charge switching units, and showcase its continued development of Human-Machine Interfaces (HMIs) designed in partnership with some of the world’s leading on- and off-highway vehicle OEMs.

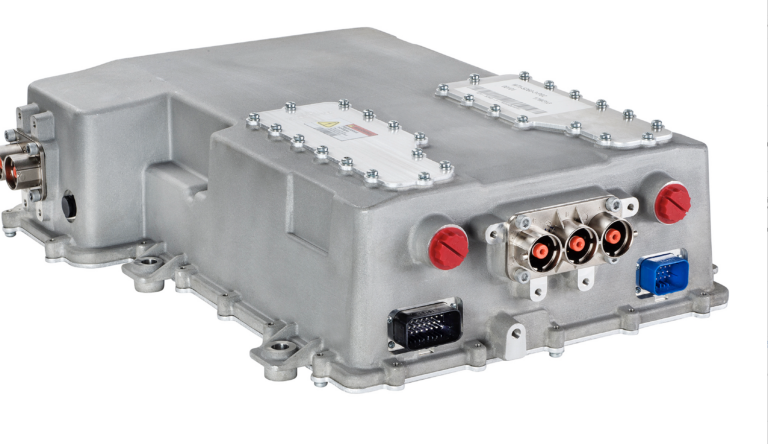

Having confirmed its continued commitment to a long-term strategy of advancing the electrification market with the extension of its traction inverter product portfolio, Curtiss-Wright’s latest CWTIs offer the most highly efficient and innovative design for use in hybrid and pure-electric applications for on-highway and off-highway commercial vehicles.

These second generation CWTI models have been engineered to be the very best performing and most efficient IGBT inverters on the market today, using state-of-the-art technology to design and ensure end users receive peak performance from a CW engineered solution. Results from extensive testing on some of the world’s most powerful and efficient electric motors have demonstrated improvements of up to 38% on peak torque and power. Furthermore, using the CWTI can improve the efficiency of the drive system (motor plus inverter) by 3% resulting in an increase of up to 14% in vehicle range from a single battery charge.

Also being showcased are the Industrial Division’s charge switch units, which function as a gatekeeper between off-board DC chargers and a vehicle’s electric propulsion system to help maintain safe and controlled connection/disconnection.

With many OEMs looking to make vehicles fossil-free in the medium- to long-term, the combination of Curtiss-Wright’s 20+ year experience of working in close partnership with OEMs to provide customized solutions that deliver world-leading EV and hybrid vehicle performance, and the knowledge gained from being a part of these OEM’s electric vehicle development programs, has proved invaluable in this dynamic field.

With OEMs of on- and off-highway vehicles developing highly-efficient, flexible and safety-critical vehicles that increase productivity, there is a trend towards replacing multiple hydraulic levers and discrete components with electronic HMIs that integrate fully into custom control boxes and armrest assemblies, providing operators a wide range of new capabilities.

For many of these applications, Curtiss-Wright has a long association of developing HMIs that incorporate multiple functions that can be operated with the use of just one hand, or via finger or thumb activation. These interfaces typically incorporate push-button switches, rotary thumbwheels and joystick paddles and levers, which variously offer switched and proportional control of a vehicle’s numerous features.