Cummins Inc will showcase its hydrogen internal combustion engine (H2-ICE) for the first time at EIMA International taking place this week (6-10 November) in Bologna, Italy.

Visitors to Hall 15, Stand A3, will see three Cummins engines – the B6.7H hydrogen internal combustion engine, the B4.5 Structural engine, and the L9 Harvest engine.

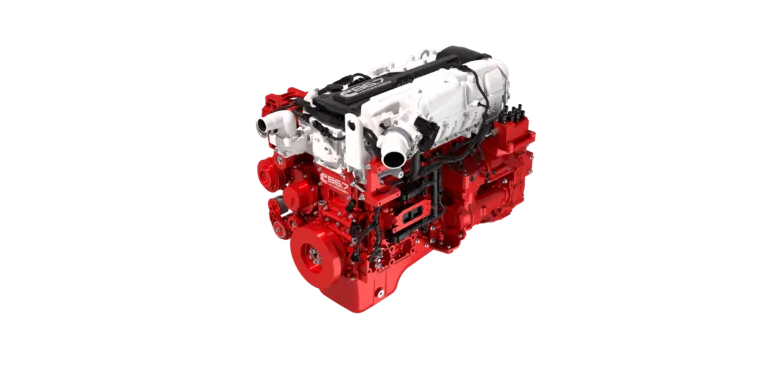

Rated at 216 kW (290 hp) and with 1200 Nm peak torque, the B6.7H provides diesel-like performance using zero-carbon hydrogen fuel for agricultural applications.

The engine’s similarity with current diesel application reduces integration complexity, while high parts commonality supports optimised parts procurement strategies for operators running mixed fuel fleets. The Cummins B6.7H provides a path to zero-carbon emissions that is familiar to OEMs and operators.

“Showcasing the B6.7H at EIMA demonstrates our ability to provide agriculture OEMs with a range of sustainable power options for all duty-cycles. The B6.7H engine’s lean combustion technology provides zero-carbon power to support our customers’ decarbonisation strategies,” says Phil Dawson, general manager-agriculture at Cummins.

Cummins’ hydrogen internal combustion engine technology is also available in a larger displacement, the X15H, with power ratings from 298-395 kW (400-530 hp) and peak torque of 2600 Nm.

Since the introduction of the Stage V emissions standard in 2019, Cummins has produced over 100,000Stage V engines across various off-highway applications.

Cummins Stage V engines, known as the Performance Series, are central to Cummins’ commitment to the agricultural sector, where it has been a key player since 1919.

With ratings from 120-160 hp (90-120kW) the F4.5 Structural engine has been specifically designed for small to medium sized general-purpose tractors. Featuring a structural cylinder block, oil pan, and gear housing along with DOC/DPF mounting flexibility; the F4.5 provides a compact and capable four-cylinder option for tractors in the 120-160 hp (90-120kW) power band.

“We are now making this product available with a structural block and oil pan for agricultural tractor applications. As part of our Performance Series range, it will deliver more machine capability and substantial productivity benefits for the farmers who operate Cummins powered equipment,” adds Dawson.

The L9 Harvest engine builds on Cummins’ proven L9 Stage V platform, but has been specially optimised for combine harvesters, which operate at higher RPMs than other agricultural equipment. To enhance performance under these demanding conditions, the design includes a larger VGT turbocharger and a reinforced exhaust manifold. These upgrades improve the engine’s responsiveness to heavy loads while delivering better fuel economy.

“Our engineers understand the unique engine requirements for combine harvesters. The new L9 Harvest has been specifically designed to perform at level that provides the necessary power for a combine while improving fuel economy,” says Dawson.

Cummins products on display at EIMA are part of the company’s wider Destination Zero strategy. Cummins has invested significantly to deliver on its Destination Zero strategy, allocating a company record $1.4 billion to research and development (R&D) in 2023, with $250 million of this spent in Europe alone.

This investment has enabled greenhouse gas reductions through improvements in fuel economy performance of diesel and natural gas powertrains, as well as development of hydrogen internal combustion engine solutions and battery electric, fuel cell electric and hydrogen production technologies.