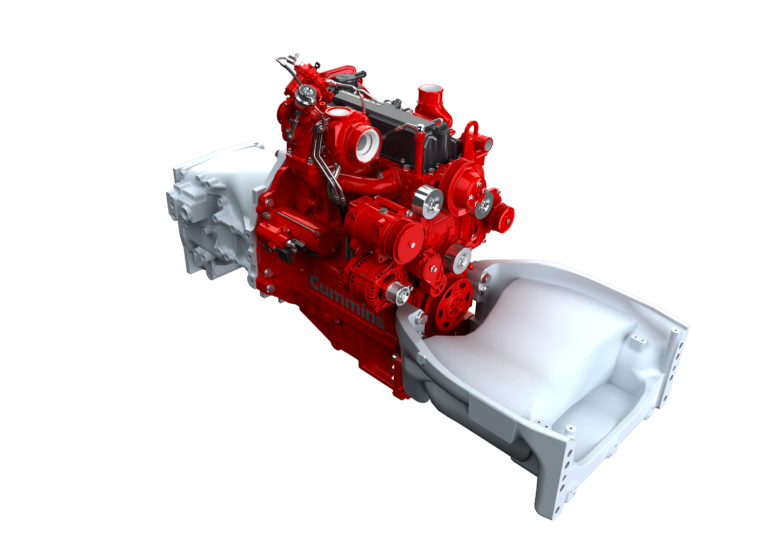

Cummins new structural 4-cylinder engine has debuted at Agritechnica 2019 in Hannover, Germany. The engine is available with 3.8 litre (F3.8) and 4.5 litre (F4.5) displacements, complementing the 6-cylinder B6.7 structural launched at the previous Agritechnica. Visitors can see the new arrival on stand D19, in hall 16 in Hannover Messe.

Signifying an extension to its agriculture line up, Cummins’ new structural F3.8 and F4.5 engines provide compact and capable four-cylinder options for tractors in the 67 – 149 kW (90 – 200 hp) power band. They are the company’s latest innovation for tractor applications and, alongside the six-cylinder B6.7 engine, expand Cummins structural product coverage from 67 to 243 kW (90 – 326 hp).

“For Stage V, Cummins technology significantly improved the capabilities of our F3.8 engine, with 33% more power and 31% more torque versus its Stage IV predecessor,” says Ann Schmelzer, general manager global agriculture at Cummins. “Pushing it up to 173 hp has made it a leader in its class. We are now making this product available with a structural block and oil pan for agricultural tractor applications. As part of our Performance Series range, it will deliver more machine capability and substantial productivity benefits for the farmers who operate Cummins powered equipment.”

The F3.8 structural engine will also be offered in a 4.5 litre configuration to extend its power capability above 129 kW (173 hp) to 149 kW (200 hp). With up to 780 Nm peak torque the F4.5 is ideal for higher powered farming equipment. Externally, the F3.8 and F4.5 engines are identical, offering tractor manufacturers flexibility with consistent packaging across multiple products and power ranges.

As with the B6.7 structural, the new 4-cylinder block and oil pan include design features to minimise weight yet provide maximum strength for engine and driveline durability.

Both F3.8 and F4.5 benefit from Cummins wastegate turbocharging as standard, with Holset® VGT™ variable turbocharger technology available on the F4.5 engine for applications requiring higher torque across a wider range of engine speeds.

“Customer flexibility has been a core consideration during the design of our new structural engine,” she says. “Both products can be tailored to suit a variety of installations with features such as the oil pan, fan hub position, turbocharger position and aftertreatment customisable to suit packaging requirements. Our electronic control capability means that performance is tailored for on-farm operation with the optimum power bulge and torque back up available to suit tractor duty cycles. The EGR-free design facilitates lower total cost of ownership for farmers through higher fuel efficiency, and less servicing with up to 1000 hours of operation between oil drain intervals.”