Volvo Penta will now be able to complete industrial engine production in the USA, after enhancements were made to its North American production facilities.

The expansion of the company’s Lexington operations in Tennessee means that orders and delivery lead times will be sped up for the North American market.

A new production line will no longer require the US arm of the company to keep a stock of completed industrial engines or import them from facilities outside of the country – which had a 12- to 14-week lead time.

“Over the past four years, our industrial business has increased substantially and we’re confident our penetration into the market will only become stronger,” said Ron Huibers, president of Volvo Penta of the Americas.

“The decision to begin final assembly at our wholly-owned facility right here in the United States was made not just to improve flexibility and lessen lead times for our customers today, but also to put us in a better position to support future customer needs as we expand our business and enter new industrial segments.”

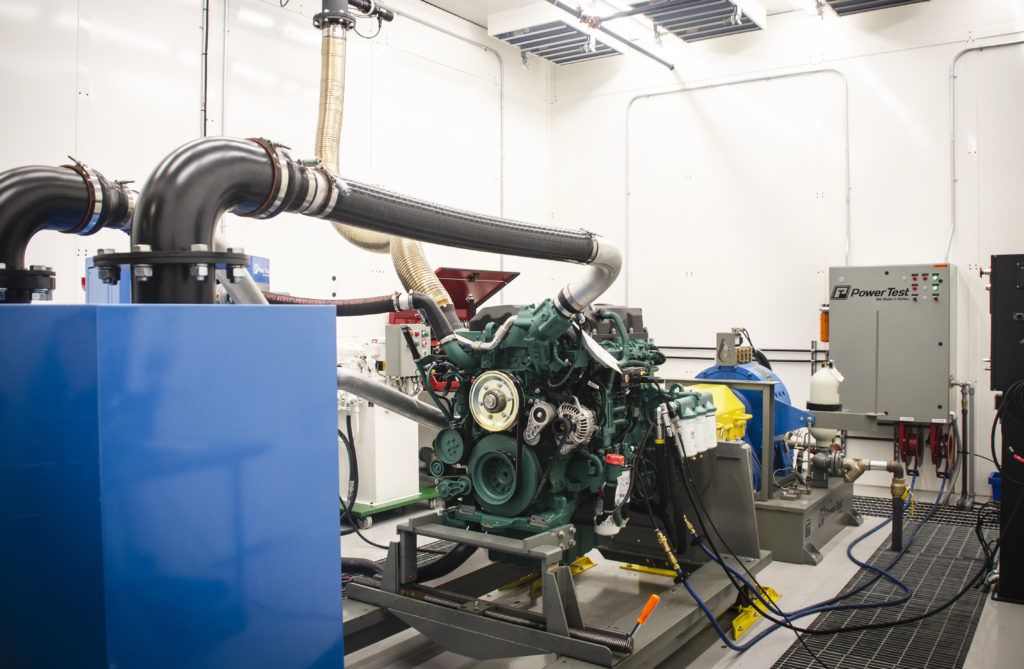

Now, a stock of base engines of D5, D8, D11, D13 and D16 models will be maintained at the factory in Tennessee, along with all accompanying components. When a customer places an order, the base engine and components are assembled to the required specification, and the unit is programmed and tested to ensure the correct performance is achieved. Orders will be delivered within two weeks.

Darren Tasker, vice president of industrial sales for Volvo Penta of the Americas, said, “In catering to the versatility of our customers’ individual specifications, we’re now able to provide them with far greater flexibility to order exactly what they need, while significantly shortening the window of delivery.”

May 11, 2018