As tractors and implements continue to grow in size, couplings are exposed to increasing wear in heavy conditions. A new innovation by Finnish company LH Lift ensures that tractors and implements remain more securely attached under the toughest conditions. Incredibly, the new coupling is also easier to manufacture, and it enables tractor operators to change the replaceable balls on the lower link arms, top links and lift rods easily by themselves.

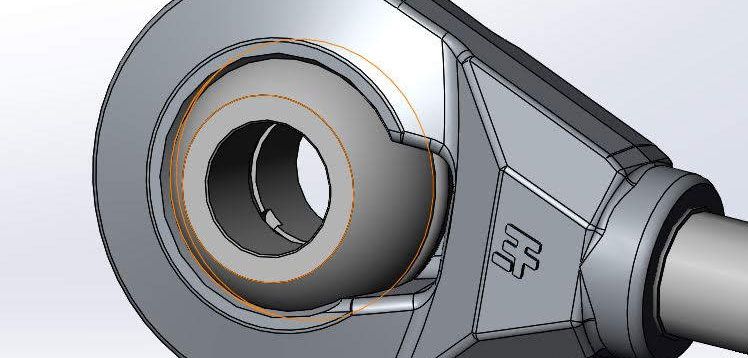

The innovation utilizes hemispheric balls that are inserted into a cavity machined into the couplings. The cavity is machined directly into the arm, and when the two hemispheric balls are inserted, they lock into position by means of a locking ring.

Since the ball is inserted directly into the lower link frame by hand, the metal around the ball does not require pressing to lock ball into place. This enables the lower link frame to be tempered instead. Tempering makes the coupling significantly more durable than pressing. Tests have demonstrated that the new type of coupling is many times more durable than traditional couplings.

While the machined ball seat has been in series production for almost four years, LH Lift has now applied for a patent for its innovative hemispheric balls. At the same time, the balls are being made available also for top links and lift rods. Based on the company’s experience with lower link arms, it expects the tempered ball seats to reduce warranty costs and enhance customer satisfaction without having to raise prices.

LH Lift is a 40-year-old family-owned company with factories in Finland and China. LH Lift is a specialist in the design and manufacture of couplings for tractors and other machinery. LH Lift is a proud OEM supplier to Valtra and AGCO.

LH Lift supplies a wide range of components, including top links and lift rods, lower link arms, lower link arm stabilizers, quick coupling hooks, rear hitches and drawbars, pivoting front linkages and accessories.

Visit LH Lift at Agritechnica Asia, Bangkok, at stand S12, August 22-24, 2018.