Cummins impressed visitors to Intermat Paris today (April 23) whin it revealed its first electrified off-highway powertrain concept. The range extended electric driveline (REEV) is suitable for a wide range of equipment including wheel loaders, mobile cranes and excavators.

Cummins Battery Electric (BEV) system will provide pure electric power with zero emissions on a single charge at the point of use, intended for the most environmentally challenged locations. It will be suitable for applications such as drills, underground mine trucks and terminal tractors.

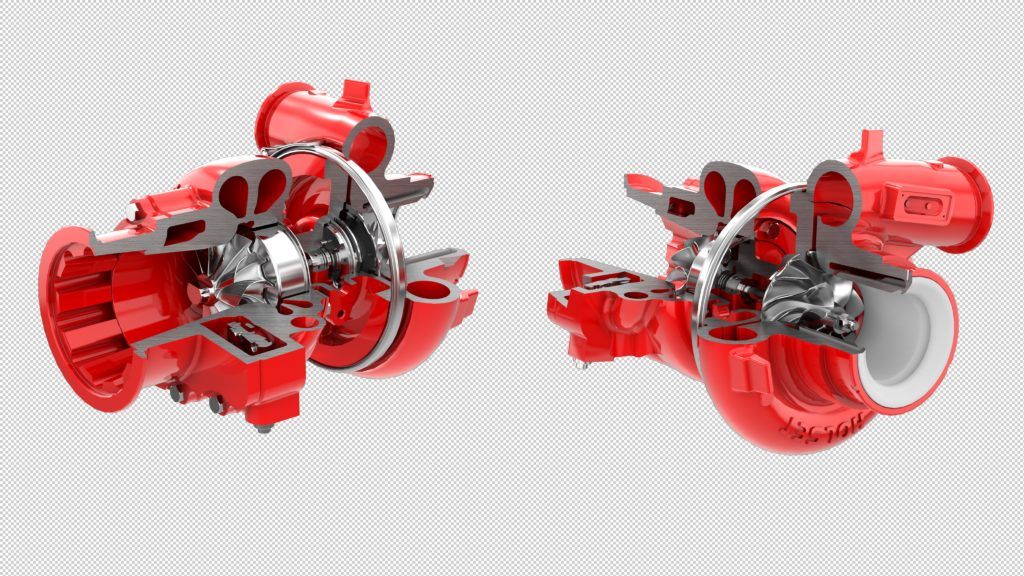

The REEV offers a balance of battery power with a compact engine-generator. It works in the same manner as a BEV but has both an F3.8 Stage V powered generator and plug-in options for charging, giving much more flexibility where charging infrastructure is not available.

The generator uses a high-efficiency traction motor which provides continuous torque of 1,850 Nm, eliminating the need for gear shifting and dramatically reducing powertrain noise. An instant peak torque boost up to 3400 Nm is available when the machine hits difficult working conditions.

“Cummins is developing a portfolio of alternative power for the industrial market, including full electric and range extending electric drivelines. These complement our Stage V clean diesels and enable us to offer the best solutions for our customers, whatever their needs,” said Julie Furber, executive director, Cummins Electrified Power Business.

“With our recent acquisitions of Brammo and Johnson Matthey Battery Systems we are building capability across the entire range of electric storage. At Intermat we are debuting our 35kWh battery pack for the first time. It can be installed singularly or in multiples to meet the needs of the equipment operation and duty cycle,” added Furber.

On its Intermat stand Cummins showed how the REEV would power a 20-ton wheel loader. The machine would be charged overnight, allowing two hours of operation per 35 kWh battery. The longer the need for zero emission operation, the more batteries needed.

“The high-density battery enclosure and engine can be sized to deliver the best balance between ultra-low emission and zero emission operation,” concluded Furber.