Using the tagline Meet the Future, mobile crushing and screening manufacture RM Group has unveiled its latest product at this year’s Bauma, including its new Rubble Master. Its modular solutions are already in series production to handle energy bottlenecks, scarcity of resources, and flexibility that is demanded by more and more customers.

The good news for the construction industry is that there is no sign of the development of infrastructure slowing down with the market still growing rapidly, especially in South America, Asia and the Middle East. It is well-known that this industry in particular is struggling with the current situation concerning the demand for energy and raw materials. In the face of this crisis, the RM Group supports its customers with consistent electrification of crushing and screening machines and presents innovations that are already in series production for cost effective and efficient crushing and screening.

“Visionary thinking alone is not enough. It is about the realisation of concepts. Customers need production-ready solutions now. That is what we can offer with our new products. Today’s demands are tougher and more complex than ever before. Since 2020, we have been coping with multiple crises. At this year’s Bauma, we demonstrate once again that we are among the frontrunners that actually bring their ideas to market,” says Gerald Hanisch, founder and CEO of the RM Group.

“All the machines are very compatible and expandable with each other, which is a huge advantage for us in the rental fleet,” says Paul Fot, one of the two managing directors of Fot Machinery GmbH. Five years ago, they bought their first RM machine from the German RM sales partner C. Christophel GmbH. Their investment has paid off. Fot Machinery now owns 15 RM crushers and screens, which they can easily rent out thanks to their intuitive operation.

“With RM machines, our customers can start work quickly. The machines are easy to operate and quickly explained. This is an essential criterion in the rental business and guarantees a low-threshold entry into the recycling business,” says Fot.

Product benefits such as the modularity and simplicity of the machines as well as the common parts philosophy are appreciated by many customers. This is also the case for the British company Chapman, how now own an extensive fleet of 20 RM machines. As confirmed by Matthew Crofts, director of Chapman: “I backed the right horse with the RM Group. Regardless of the application, I can rely on the quality of the crushers and screens and have maximum flexibility.

Whether diesel-direct or hybrid drive, I can operate each of the machines as a stand-alone solution, or combine them in a machine train and save fuel at the same time. It was this comprehensive principle that was decisive in choosing RM as our partner because it has helped us to optimise many processes and save costs.”

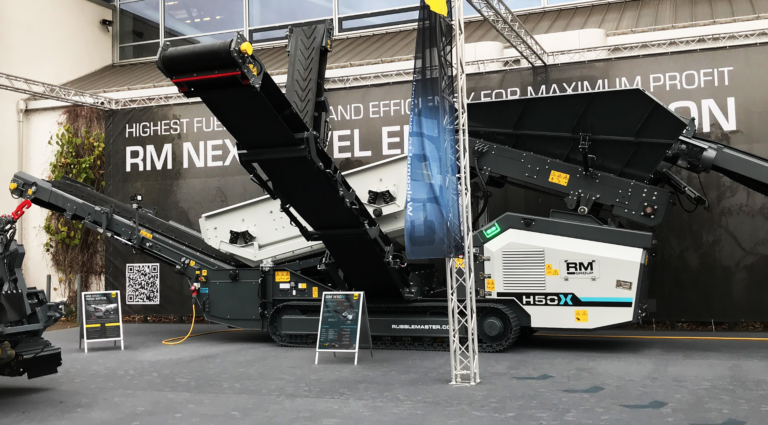

Newly developed RM H50X hybrid screen proven to save time, money and emissions Save up to 50% on fuel in a hybrid crushing and screening train? This is exactly what the brand new RM H50X hybrid scalper which will be presented in the outdoor area at bauma, makes possible. Rubble Master is already demonstrating how energy efficiency has become reality on the construction site.

With more than 30 years of experience in electrification at RM Group, the launch of the hybrid screen sees another masterpiece of efficiency, versatility and simplicity arrive on the market. As a hybrid variant, the screen can also be operated fully electrically to notch up zero CO₂ emissions. In addition to efficiency, the new RM screen delivers impressive modularity and versatility.