New technology from Wirtgen that, for the first time, makes it possible to accurately and quickly documents the amount of milling work completed is expected to make the task easier, faster and more cost-effective.

Capable of being retrofitted on the OEM’s large milling machines built and in operation from 2010 onwards, the Performance Tracker removes the need for contractors to mill more than is specified or rely on expensive survey technicians to precisely quantify the amount.

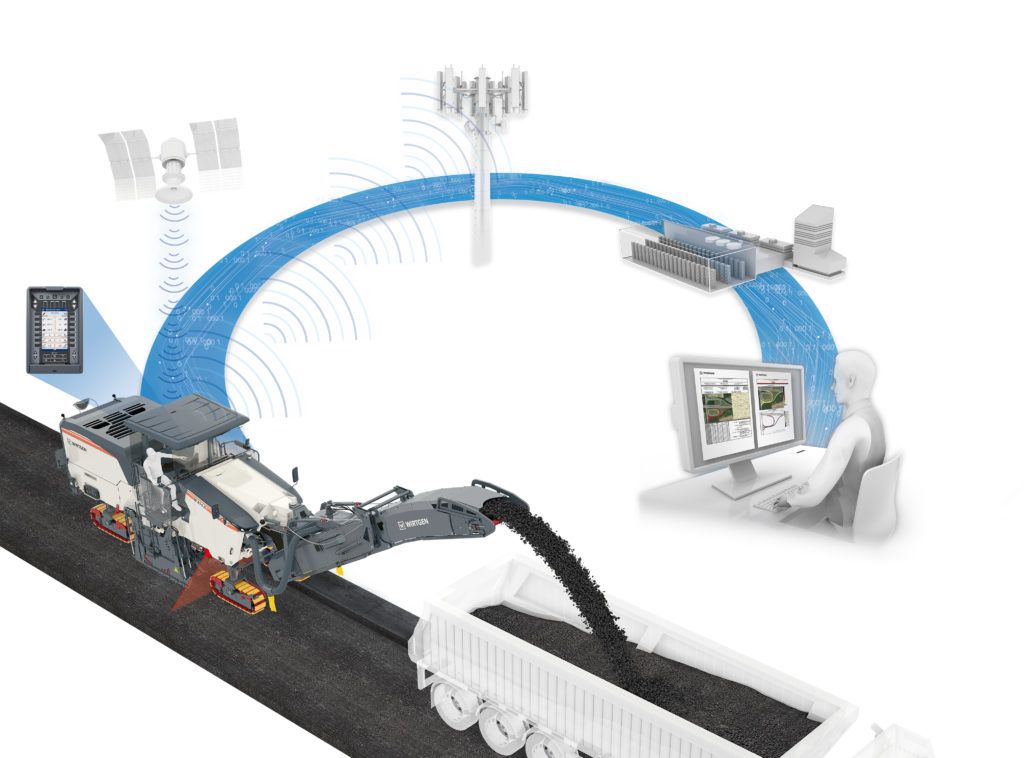

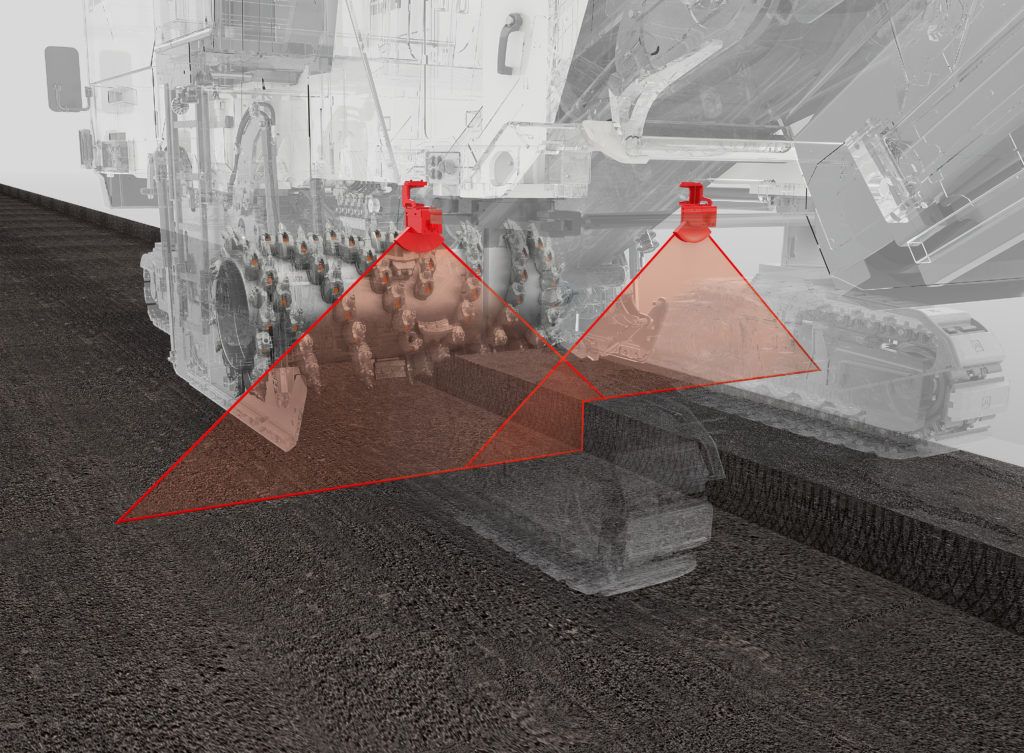

Making use of the infrastructure of the firm’s existing telematics system, the new solution uses a laser scanner to measure the cross-sectional profile of the area to be milled. Surface milling performance and volume are calculated using GPS positioning and other sensors, the machine is then able to continuously track the work in real time on the vehicle’s control panel display.

Making use of the infrastructure of the firm’s existing telematics system, the new solution uses a laser scanner to measure the cross-sectional profile of the area to be milled. Surface milling performance and volume are calculated using GPS positioning and other sensors, the machine is then able to continuously track the work in real time on the vehicle’s control panel display.

Upon completion of the milling job, a report with all of the relevant performance and consumption data is automatically generated in both Excel and PDF format which is emailed to the machine operator.

The efficiency of the process means that work can be billed quickly on the basis of transparent and accurate information.

Additional benefits of the new system are that site costs can also be determined.

“For example, the accurately measured performance and consumption data not only makes it easier to evaluate the efficiency of current and future construction sites,” explained a Wirtgen Group in a statement. “In addition, the data can be used to easily compare the machines with other cold milling machines in the machine fleet – a valuable basis for the machine operator to decide which milling machine is the most efficient solution for which job.”