Polygon Company, a leading producer of composite tubing, bearings and pneumatic cylinders, will be highlighting its line of high-performance composite plain bearings at next week’s ConExpo in Las Vegas.

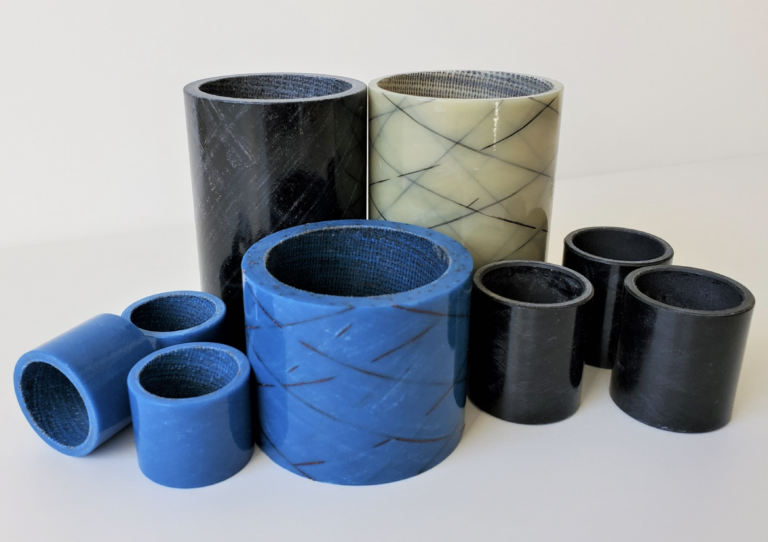

The high-performance custom-engineered and standard composite plain bearings on display are ideal for challenging construction equipment applications, including wheel loaders, excavators, back hoes, and compact track loaders, as well as other applications requiring pivot joints with a long life-expectancy. Featuring high load-bearing capacity, low frictional values, and corrosion resistance, the Polygon composite bearings are self-lubricated, requiring no greasing. This reduces maintenance labor costs and increases the interval before maintenance is required on rental equipment. It can also lower the number of greasing locations, ultimately resulting in fewer equipment warranty claims.

Also on display will be PolySlide composite tubing for pneumatic and low-pressure hydraulic applications, including fifth wheel actuation, gate valve actuators, water treatment flow control mechanisms, and tie rod cylinders. PolySlide tubing replaces metallic material in a variety of cylinder applications. Supplied as a cylinder tube ready for customer assembly, or as fully engineered cylinder assemblies for equipment manufacturer applications, the tubing is made of continuous filament-wound glass fibre and polymer resins. The fibreglass filament and resin materials combine together to form a high strength component that exhibits dimensional stability, is non-corroding, impingement resistant and is non-conductive. PolySlide is the solution for service in harsh environments. The cylinder tubing performs in high and low temperatures, grease, grit, salt, chemicals and other extreme conditions.