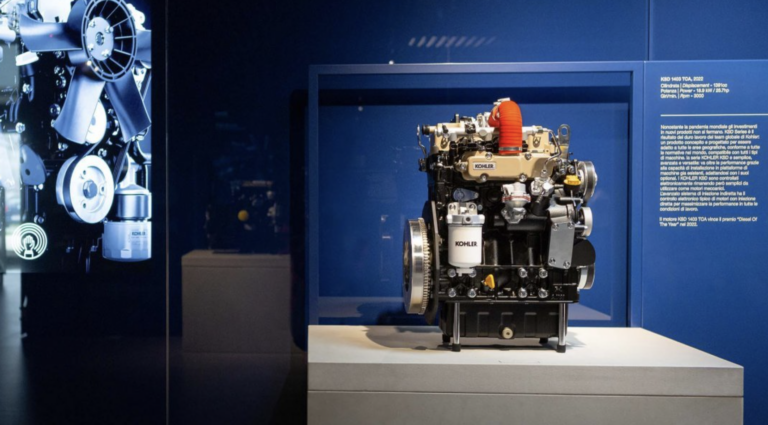

Diesel Of The Year is back at Kohler, which has won the award for the third time in ten years with its new KSD 1403TCA engine. The award winner is part of the new KSD (Kohler Small Displacement) engine series, designed to adapt to all geographical areas, comply with all regulations worldwide, and be compatible with all types of machines.

The KSD series is the result of a totally market and customer-oriented approach. It is simple, as it can be easily integrated with the increasingly complex electronic systems of industrial machines, which are constantly evolving. It is advanced, as it allows different customisations for all work cycles, as well as offering the possibility of data exchange with a reduced number of physical connections. It is versatile, being adaptable to the machines without need for modifications or redesigns.

.jpg)

The KSD series is the result of a totally market and customer-oriented approach. It is simple, as it can be easily integrated with the increasingly complex electronic systems of industrial machines, which are constantly evolving. It is advanced, as it allows different customisations for all work cycles, as well as offering the possibility of data exchange with a reduced number of physical connections. It is versatile, being adaptable to the machines without need for modifications or redesigns.

This version boasts a peak torque of 120 Nm @ 1400 rpm, a displacement-to-torque ratio competitive with engines of the same displacement but with outputs between 30 and 42 kW that need aftertreatment systems. The sub-19 kW engine complies with current global emissions regulations: EU Stage V, US Tier 4 Final and, by the end of this year, also China Stage IV. Consumption is reduced by optimising engine speed and controlling the hydraulics. Service intervals are maximised and total cost of ownership is low, thanks also to smart prognostic and diagnostic functions.

.jpg)