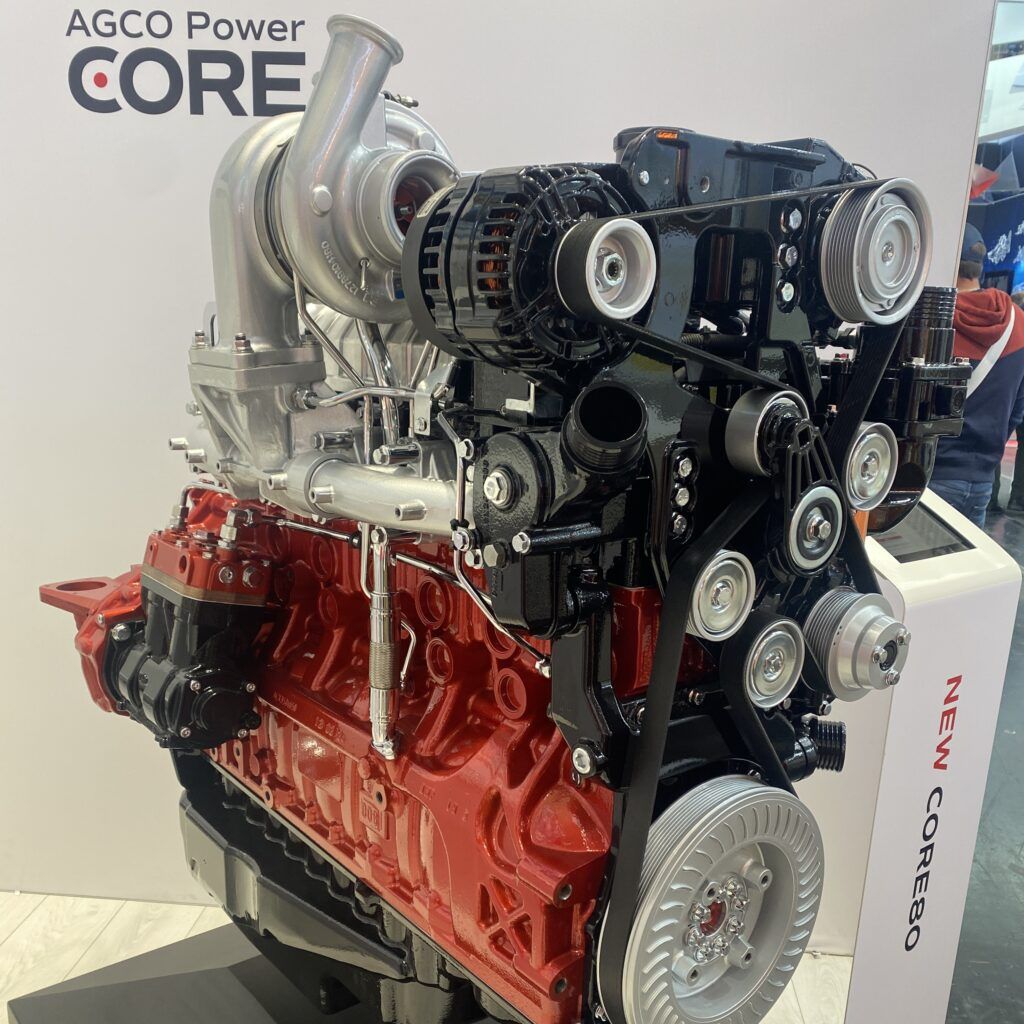

At this week’s Bauma Munich, AGCO Power (booth 541 at Hall A4) unveiled its new CORE80 engine. The CORE80 is the third member in AGCO Power’s CORE family, with the first vehicle equipped with the CORE80 engine will enter mass production at the end of 2025.

“The eight-litre CORE80 completes the current CORE engine family and compliments the existing five-litre CORE50 and the 7.5-litre CORE75 in the higher power range with multiple technological innovations,” said AGCO Power’s director of engineering, Kari Aaltonen. “We are very proud of this engine.”

Key features of the CORE80 engine include a maximum power of 252 kW @ 1500-1700 RPM, a maximum torque of 1680 Nm @ 1200-1400 RPM and exceptionally good fuel efficiency across a wide RPM range and power demands.

ABOVE: the CORE80 by AGCO Power features a maximum power of 252 kW @ 1500-1700 RPM

The Variable Geometry Turbo (VGT) offers several advantages over traditional turbocharging technologies. VGT allows the engine to achieve improved low-end torque and reduces turbo lag. Additionally, VGT enables maximum torque and power across the entire RPM range, enhancing engine performance under heavy loads. VGT also regulates airflow more precisely, leading to cleaner combustion and a more environmentally friendly engine.

In addition to the engine braking capability, the CORE80 is the first AGCO Power engine to offer over-the-air (OTA) connectivity to its engine control unit, enabling remote diagnostics, effortless monitoring and simpler updates. This improves reliability and makes fleet management easier.

The CORE80 engine represents AGCO Power’s commitment to innovation and sustainability. Its design considers both performance and environmental friendliness, making it an ideal choice for modern construction and agricultural machinery.