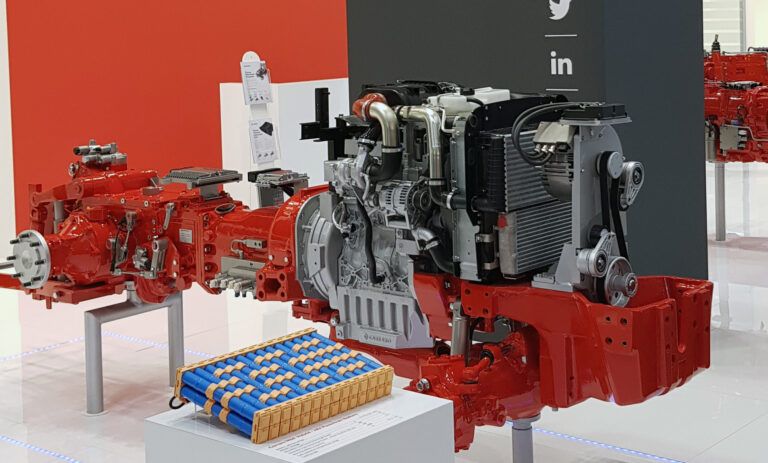

Carraro has unveiled its mild hybrid powertrain to the world at Agritechnica this week.

Designed for specialised tractors, the 3E22 is being presented for the first time at the show in Hanover, Germany.

A new 3E22 endothermic engine (3 cylinders, 2227 cm3, 55kW). Developed for specialised agricultural applications, is also available in a version that can be used on worksite machines and was designed to comply with the emission limits of T3B, Stage V, China IV and Bharat IV.

Thanks to the integration between the internal combustion engine and an electric motor – 48V from 20kW, the powertrain (transmission combined with a front axle with IFAS suspensions) offers the agricultural world the ideal solution for guaranteeing the same advantages as a 100 hp engine whilst optimising fuel consumption.

This is made possible by the reduced size of the endothermic engine and the smart management of the electrical boost function that can sustain and optimise the diesel engine overload (e.g. during transportation and work).

This is made possible by the reduced size of the endothermic engine and the smart management of the electrical boost function that can sustain and optimise the diesel engine overload (e.g. during transportation and work).

Thanks precisely to the downsized internal combustion engine – just 55 kW – this solution also avoids the need to install the SCR catalytic converter to meet the European STAGE V standards; this means undoubted advantages for the specialised tractor in terms of overall dimensions and cost.

The structure of this new powertrain confirms the outstanding skills of Carraro Group, including a knowledge of electrification built up in over 25 years in the material handling sector, with particular reference to electric drive transmission systems.

The new Mild Hybrid powertrain will be attached to the Carraro Ibrido tractor that won two awards during the EIMA 2018 (Technical Innovation and Blue Award for attention to the environment).

This tractor-concept, that has met with a lot of praise in just a few months, was designed to provide a response for a market that’s increasingly asking for machines with engines that guarantee low emissions and reduced consumption.

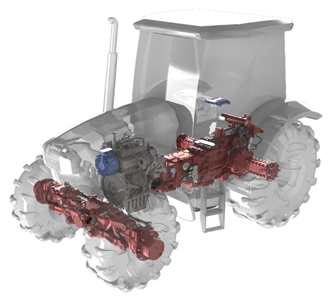

Technically speaking, the Carraro Ibrido represents a real turning point in the agricultural mechanisation of specialised tractors. It’s based on a complex parallel type of architecture. The internal combustion engine and the electrical motor are used for the mechanical propulsion of the tractor, via a traditional 24 + 24 synchronised mechanical transmission.

The combination of the engine and the electric motor enables the power delivered to be optimised in accordance with the various operations to be performed by the tractor. More specifically, operators can choose whether they wish to work in:

– pure electric mode: for use inside closed structures, greenhouses and stables or for municipal applications

– diesel only: for road transportation or when not carrying/towing heavy loads

– hybrid: for transport operations when towing or carrying loads, or for heavy PTO operations

With this architecture, the auxiliary systems are managed by dedicated electric motors, which serves to further rationalise usage.

The new hybrid system will reduce consumption, eliminate emissions (in full electric), offer greater productivity, limit maintenance costs (thanks to the reduced use of the endothermic engine), ensure the quality of the cultivation (thanks to reduced Co2 emissions) and lower the level of noise and vibrations.