ABB and Komatsu have signed a strategic collaboration agreement to work together on the development of integrated solutions that will help bring net zero emissions closer for heavy industrial machinery.

Decarbonisation of mobile mining equipment is needed to help mine operators achieve their greenhouse gas reduction targets. ABB and Komatsu’s collaboration is geared towards reducing diesel consumption and ultimately eliminating it through the electrification of mine operations.

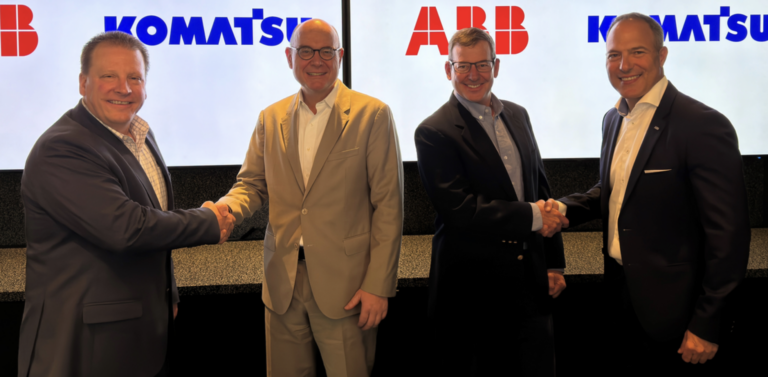

“We’re pleased to embark on this collaboration with ABB and are excited to leverage one another’s industry leading products and technological expertise to help move mining operations toward net zero emissions, empowering a sustainable future where people, business, and the planet thrive together,” says Dan Funcannon, senior vice president of surface haulage for Komatsu.

Recognising the varying stages of electrification standards across the mining industry, ABB and Komatsu are focusing on haulage, loading, and auxiliary equipment. This approach aims to build a comprehensive portfolio of production and support equipment to accelerate adoption into its customers’ operations.

“By working together, we will tackle electrification and make a revolutionary difference to the way mining companies operate their sites in the near future,” says Joachim Braun, division president, ABB Process Industries. “We recognise the strategic importance of this agreement and believe there will be mutual business benefits and potential technology solutions for the mining market. Collaboration across the industry has already been proven to enable real and faster progress and we look forward to driving what happens next.”

For a firsthand look at the collaboration, Komatsu will feature the ABB’s eMine Robot Automated Connection Device (ACD) at MINExpo 2024. The Robot ACD is planned to be a fully automated interoperable connection device part of the eMine FastCharge solution for future battery-electric trucks.