This decade, combine harvesters have become significantly larger and more powerful – and back in 2016 the Ajuria concept, designed by Alberto Seco and published in the pages of iVT, predicted this trend. Now, Seco has returned to the design to update it for a new era

When the first version of the six-wheel Ajuria combine harvester concept was published in the March 2016 issue of iVT, only a few combines were available in the Class 10 category (currently defined as exceeding 680hp). Back then, images of Class 10 prototypes under testing could be found on the internet, for example a massive, wide and long John Deere harvester. There were also some pictures of a red machine with huge rubber tracks that seemed to be a new Massey Ferguson.

One year later, AGCO unveiled the first units of this Ideal Series built in the former Laverda plant at Breganze, Italy. The red colour had been turned into high gloss black to serve the three AGCO brands: Massey Ferguson, Fendt and Challenger. By then the New Holland CR10.90 Elevation was also launched, with

a maximum power of 653hp, thanks to its FPT Cursor 16 engine.

The biggest headers provided by the OEMs were the 13.10m (45ft) mounted on the North American Massey Ferguson 9895, Case IH Axial-Flow 9240 and New Holland CR10.90. A considerable grain tank of 14,448 litres (410 bu.) was fitted in the Case IH and New Holland models. And, as a dimension related to the size of the threshing systems, the Massey Ferguson Delta 9380 was fitted with twin rotors of 4250mm length.

All these specifications were exceeded by the Ajuria concept combine with a 850hp power unit, a 16,500-litre grain tank and headers from 50-60ft.

Meeting the design challenge

In 2016, the Ajuria high-performance combine (which takes its name from a Spanish OEM that made agricultural machinery in the first half of the 20th century) tried to meet an iVT Design Challenge based on the following question: “What effect would adding at least one extra axle to a traditionally two- axled machine have on its design, dimensions and performance?”

The addition of an extra pair of wheels to a combine harvester would allow for the development of a higher-performance machine, supporting massive loads due to the huge header, grain tank and threshing system. The front bogie axle drive system would erase the need for dual tyre combinations on a typical single front axle. This configuration would also make a longer system possible, ideal for effectively managing all the straw supplied by the wider header.

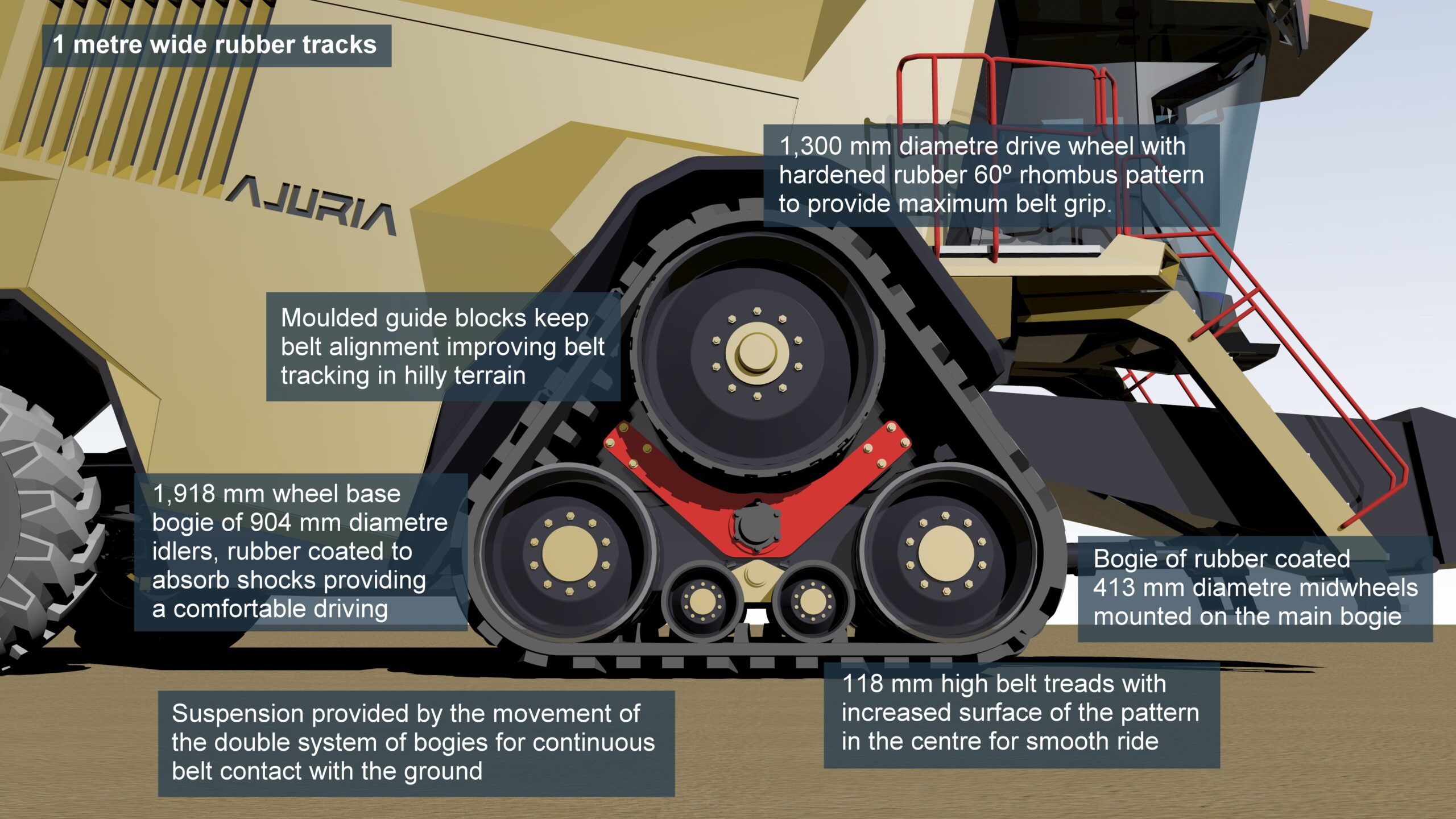

The rubber tracks had significantly improved performance on big combines since the introduction of the caterpillar system (which were first developed for the Challenger farm tractors) on the Lexion range of combines by Claas.

However, the launch of the new AGCO Ideal opened the door to developing bigger systems with different configurations. Since 2017, the size of combine harvesters has kept growing to develop a proper market of Class 10 combines, and rubber track systems have been instrumental to cope with big loads on the front axle.

They have provided harvesters with even distribution of weight with reduced ground pressure and improved tractive effort. Thus, the Ajuria II Series Class 10 concept combine has been fitted with a pair of rubber tracks.

A high-performance market

How would the concepts of 2016 stand in today’s market? All OEMs have increased the size of grain tanks exceeding 16,500 litres and the new Case IF AF11 combine has reached a capacity of 19,980l (567 bu.).

The former Ajuria combine had an excessively long cab, and now, it has been reduced for the tracked model to leave more room for a bigger tank.

To increase headers width up to 18m (60ft), the CNH group enlisted McDon, a supplier of specialised headers. For the Ajuria combine, the former 50-60ft headers had been designed as foldable units to facilitate the transport of the combine without dismounting the header.

Ajuria’s threshing and separation system, which consists of a set of transversal concave and threshing drums and two counter-rotating diameter rotors, is the standard configuration for the current Class 10 combines market, with twin rotors measuring under 5m in length.

The Ajuria II Series concept harvester keeps the foldable centred unloading auger, over the grain tank, to offer truly flexible grain unloading all around the combine allowing the unload towards both sides.

A new convenient access to the cab has been designed for both sides by means of dual ladders that can be placed on longitudinal or transversal direction to offer two different ways of access to the cab.

This article first appeared in the iVT Off-Highway Annual 2025 which is available to read HERE