In collaboration with experts at CNH Industrial and Italian alcohol brand, Martini, two groups of Industrial Design Masters students at Italy’s Istituto Europeo Di Design were given the task of designing an agricultural vehicle that not only improves the efficiency of farming tasks, but also the working conditions for operators

In 2024 the CNH design team once again collaborated with Istituto Europeo di Design (IED). Together with its project partner, the historic Italian brand, Martini, CNH Industriaal challenged students on the master’s course in Transportation Design to reimagine a self-propelled grape harvester.

New Holland has over 50% of the global market in this product segment and the students were tasked with finding innovative ways to improve the harvesting process, while also improving working conditions. They were also challenged to integrate new technology and sustainable materials.

The students conducted thorough research and developed creative ideas for a versatile machine aimed at enhancing both working conditions and productivity. The goal was to create a new type of harvester that bridges the gap between hand-picking and mechanized harvesting. Emphasising sustainability and leveraging advanced technology for maximum efficiency were primary considerations. Two teams of design students crafted their unique vision of the future.

Project SideWays

This team, comprised of students Alessandro Ravedati, Francesco Raffaele, Megh Bath and Santiago Espindola, set out to improve the working conditions of manual grape harvesting.

Grape harvesting is often done on hilly terrain, which is not ideal for large, mechanized harvesters, however manual harvesting is slow, costly and creates a lot of human fatigue.

To address this situation, the designers studied the various pain points and created a small machine that is capable of entering into smaller vineyards. The machine can work on inclined fields due to the gyroscopic suspension system, while the operator remains in a comfortable upright position. Body support protection helps significantly to improve working conditions.

Showing that good design can create a harvester with style, the team were inspired by the Martini bottle, mixing this inspiration with important functions. The machine is fully electric and runs autonomously, allowing the operator to focus on the grape picking at an ideal height and posture. A storage container is integrated into the machine to receive the grape collection and special flotation tyres together with rear tracks help to minimise soil damage. Intelligent glasses can be used along with the Shear Glove to detect and cut the correct grapes to make sure that the harvest is of high quality.

Project Herbini

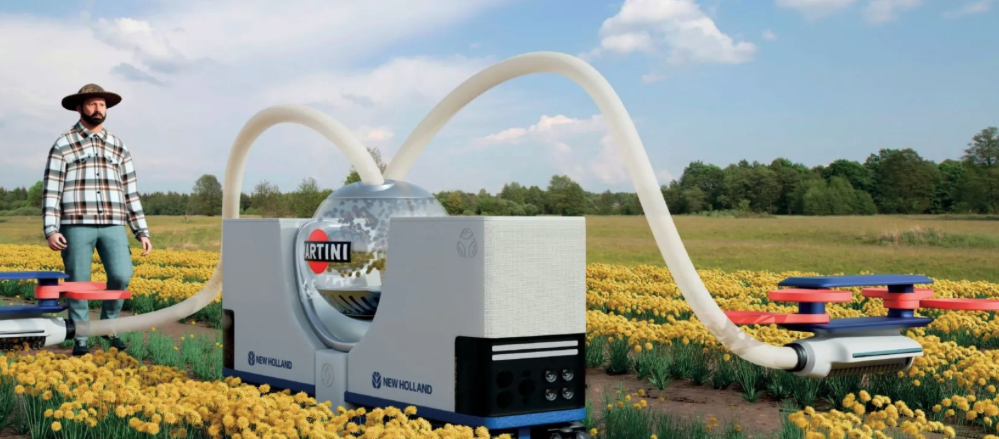

CNH’s other team of design students, including Marina Cerfeda, Marica Flagiello, Jorge Garcia Del Rio and Felipe Rey Barberi, created an autonomous system for harvesting aromatic herbs. This system has been designed to work in a two-hectare space comprising 90 rows with 65kg of flowers in each. Each storage box has the capacity to hold one row of flowers.

Flying electric drones guide harvesting rollers which, with the help of sensors, pick only the herbs that are ready for harvesting. Once collected, herbs are swallowed up by tubes connected with the ‘alambicco’, which brings the flowers into the storage boxes. Once these boxes are full, they detach from the rover autonomously, reaching the in-field collection point. In the meantime, an empty, replacement box reaches the rover through a network of sensors and GPS signals.

The system is equipped with two harvesting drones and boxes, which decrease the harvesting time by 50%. The inspiration comes from the drinking experiences of Martini and the preparation of vermouth inside the factory. The central element of the system is ‘alambicco’: the shape recalls the Martini glass and the copper still, while the tubes are reminiscent of straws in cocktails.

This article first appeared in iVT’s 2025 Off-Highway Annual