Hydraulic systems are becoming increasingly complex, working pressures are getting higher and the number of actuators to be controlled is increasing. As a result we are seeing a constant increase in manifolds and, modular or not, valve blocks with integrated functions within the hydraulic sector.

These manifolds and valve blocks are also used under increasingly extreme conditions. These include the agricultural sector (manure and fertilisers, herbicides, pesticides), the mobile sector (salt for icy roads), offshore (salt), oil and gas (salt/high ambient temperatures) and industry (detergents, high ambient temperatures).

Protection of the manifolds by a coating (wet paint, often a multilayer system) is a possible option, but it is invaraibly too expensive, does not provide sufficient protection in practice and during disassembly (maintenance/revision) there can be problems to disassemble and assemble the hydraulic system without contamination (e.g. paint particles). A high corrosion resistance of the valve block is often a requirement with regard to the operational safety of the hydraulic system and a solution to prevent contamination during the above mentioned disassembly and assembly is often desired.

Electroplating specialists Galvano Hengelo B.V. started 10 years ago with the treatment of hydraulic manifolds and components and has since become fully high adept in this field. Today, manifolds, valve blocks, screw-in parts (e.g. cartridges, plugs), cylinder tubes and rod guides (cylinder glands) are treated with zinc-nickel. It can be applied on steel and cast iron like GGG30, etc. With the appointment of Ivo Willemsen as general manager in 2017, a man who earned his spurs with hydraulic companies like Parker, it was time for a shake up.

The treatment against corrosion of manifolds and valve blocks is not new. Whereas in the past mainly zinc and electroless nickel were used, we are now increasingly seeing a shift towards zinc-nickel. The layer thicknesses required for zinc or nickel to provide serious protection against red rust (250 hours Neutral Salt Spray test or NSS) will be 30 μm or more. This immediately leads to the undesirable side-effect that a layer thickness builds up in precisely fitting cavities, with the result that the hydraulic components to be installed no longer fit or function properly.

Often these cavities are now reworked after treatment: unnecessarily rising costs, risk of product contamination and part of the layer is lost again, resulting in the loss of the desired corrosion protection. In contrast, a zinc-nickel layer (that is an alloy layer electroplated on the metal product with a content of 12-16% nickel and the rest zinc) from 5-15 μm that reaches under NSS test conditions a protection against red rust of at least 1000 hours. Of course, this galvanic layer is Cr6 free and is excellently suited as an adhesive layer for a possible (cosmetic) paint coating.

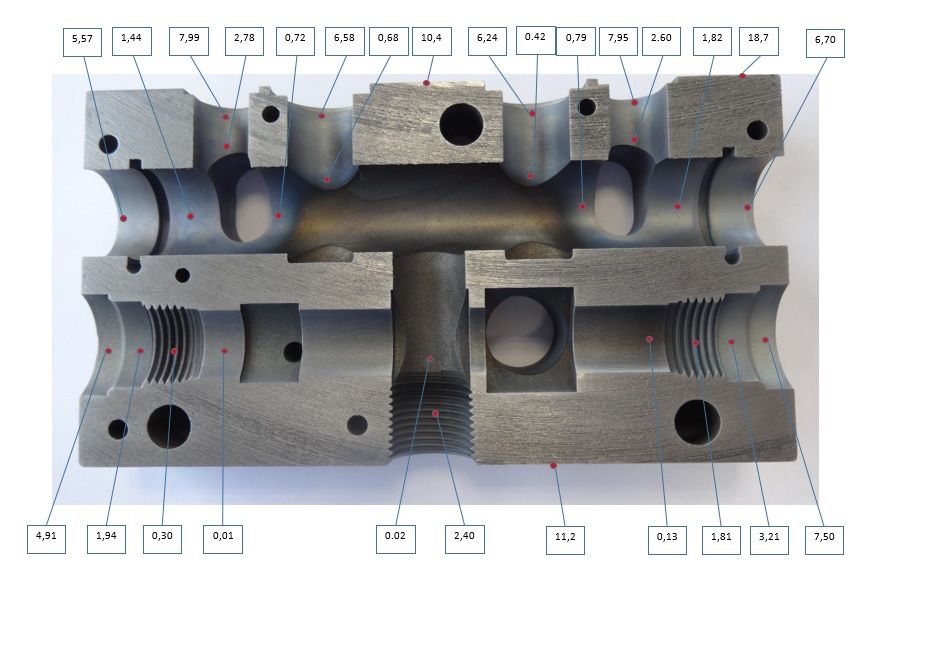

Another major advantage is that the thickness of the layer build-up in the cavities can be influenced by correcting the process settings and product handling in such a way that the layer build-up in the cavities decreases very quickly to 0 μm. This makes it possible to keep threaded connections and holes with fittings within the tolerances without corrective measures.

A major challenge is the protection of the untreated surfaces of the manifolds.

“All internal channels in a manifold will not have zinc-nickel deposition because they are not directly in the current field between anode and cathode,” says Willemsen. “During the process, however, they will be exposed to the various treatment fluids, which in a standard process leads directly to red rust (fly rust). Something that is absolutely a no go area with this type of product. Through extensive testing, our company has succeeded in developing a process that allows the hydraulic components to leave the treatment process clean and in perfect condition, than means without corrosion and contamination of the internal bores and channels.”

“All internal channels in a manifold will not have zinc-nickel deposition because they are not directly in the current field between anode and cathode,” says Willemsen. “During the process, however, they will be exposed to the various treatment fluids, which in a standard process leads directly to red rust (fly rust). Something that is absolutely a no go area with this type of product. Through extensive testing, our company has succeeded in developing a process that allows the hydraulic components to leave the treatment process clean and in perfect condition, than means without corrosion and contamination of the internal bores and channels.”

After passing through the galvanic process, a meticulous inspection is carried out on each block. Wherever process liquids are still present, they are removed. In addition, each block is checked for cleanliness and possible irregularities. As even the smallest particle can lead to major problems in the hydraulic system into which the manifold is later inserted. For this purpose all process baths are continuously filtered with a 10 μm filter.

After this test, each hole is preventively coated with an anti-corrosion agent, the thickness of the layer of parts in the batch in question is measured and the block is packed so that it stays clean and dry.

In order to further optimise the above process and also to be able to treat the increasingly complex manifolds, Galvano has started to actively rotate the manifolds during the electroplating process. A great advantage is that the distribution of the layer thickness can be further improved and also a rinsing of blind holes, in which no liquid circulates during a standard treatment, can be achieved.

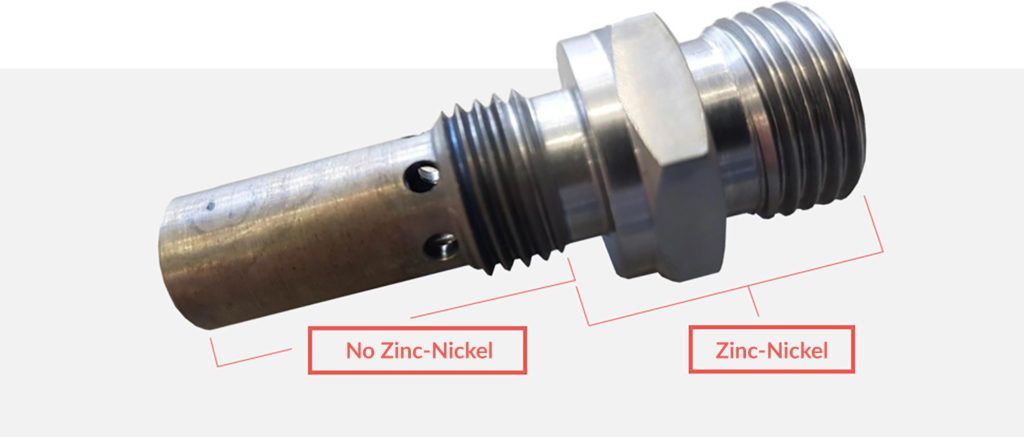

Another new development is the treatment of components such as cartridges and plugs that are screwed into the manifold. It is of course nice that the manifold has a protection of more than 1000 hours NSS, but for the components this is desirable. So far this has been solved by using standard galvanised parts with a much lower degree of protection or stainless steel parts, which are much more expensive.

Very precise tolerances often play a role in the treatment of such components, even layers of about 5mμ are too thick. Also customers want to have screw-in parts without zinc-nickel in a manifold treated with zinc-nickel due to a higher friction coefficient of the threat connection.

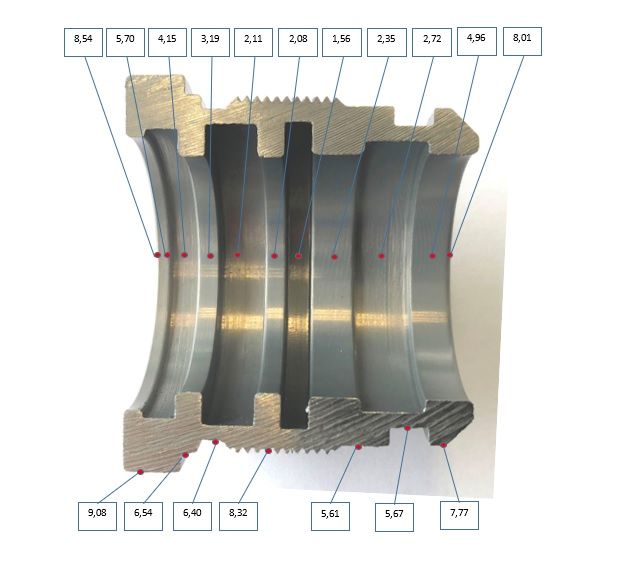

Galvano Hengelo has developed a new method for this purpose, whereby the parts are only partially treated during the galvanising process. The parts that come outside the manifold are treated with zinc-nickel. The internal parts, which often have precise shear settings, are not treated. As these are in oil during the use of the block, the corrosion pressure is not important here.The company has also started to cylinder glands for hydraulic cylinders. Galvano Hengelo has been treating the cylinder tube for some time, but the market’s desire to treat rod guides also led to more headaches.

The challenge for Galvano was not so much to treat the outside of the cylinder gland, but the inside. Often a corrosive liquid (like sea water) enters the cylinder gland with the withdraw of the rod and can cause rust between and in the grooves of the wiper and the seals. By adjusting the process and rotating the cylinder gland during the treatment, they are also able to obtain a zinc-nickel coating in the grooves that provides corrosion protection for at least 500 hours NSS on the inside. The outside is with no question minimal 1000 hours. Here too, the applied layer thickness is only a few microns, which means that critical dimensions and tolerances are only slightly changed.