Where there used to be a farmhouse and barn, there is now a highly efficient agricultural business. There’s no question about it: agriculture is becoming increasingly digital. Sensors play a key role in this. The little all-rounders are helping to solve efficiency and sustainability issues in the industry. How does this work, exactly?

**

A farmhouse with a barn. A few chickens are scratching in the yard. The cows are milked by hand twice a day. A lonely tractor chugs across the fields. And the adjacent forest is managed by the farmer with his logging horse Toni. This idyllic picture of farming hardly exists today. The consumer market is tough, the challenges are becoming ever greater, and many an old farm has evolved into a highly efficient agricultural business. The industry has also caught up enormously in terms of digitalisation over the past ten years. In addition to wheat, corn and soybeans, more and more farmers are harvesting something else: data. About the health of their piglets. About the milk yield of each individual cow. About the condition of the soil. And about the minimum fertilizer use for maximum crop quality. The nuclei for all this information are sensors.

More comfort for long harvest days

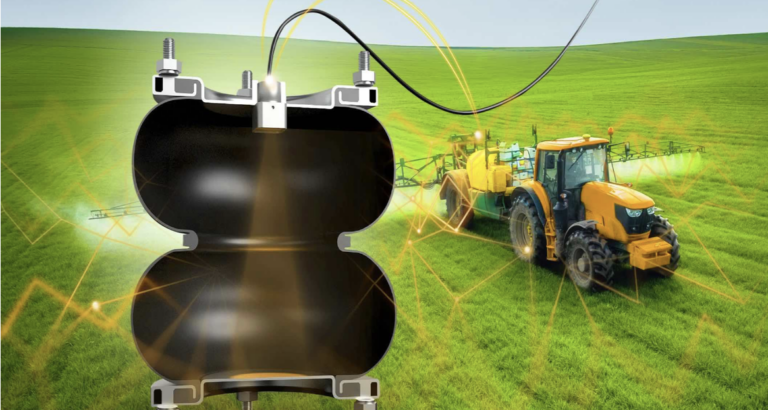

Continental are no livestock professionals. But its experts are very familiar with the sensors used in agricultural applications. “With sensors, we can, among other things, make the analog air springs of undercarriages, cabs, and seats of agricultural machines ‘smart’ – and thus significantly increase comfort for the driver,” explains Carsten Klages, off-highway expert at Continental and marketing executive for air springs in industrial applications. One example is the air springs for the front axle of tractors, for which Continental is the sole supplier.

When these sensors are combined with other components, for example valves and other actuators, as well as the appropriate control software, they are the first step towards Agriculture 4.0. One concrete example of this is the Electronic Air Spring Damping system (eASD), an electronically controlled suspension and damping system for vehicle cabs that automatically adapts to uneven ground conditions, thus increasing future comfort for all those who spend twelve hours or more at the wheel of a harvesting machine during harvesting season.

Small but mighty: sensors are already all-rounders today

However, eASD in agriculture is still rather a thing of the future. HPTA sensors, on the other hand, can already help solve important efficiency and sustainability issues in the industry today. HPTA stands for “height,” “pressure”, “temperature “and “acceleration”. Depending on the application, the sensors can measure just one of these values, a combination of several, or even all parameters.

One example: In seeding and planting machines, hydraulic elements are often used to distribute the individual seeds. However, this technology has several disadvantages: For one thing, there is always the possibility that the hydraulic oil could leak – with negative consequences for plants, soil and the environment. Secondly, the farmer must do it himself and set the planting height to a predefined level on a five-step scale, which then applies to all the seeders’ planting rows. And finally, this setting subsequently remains unchanged, regardless of changes in the soil conditions in the course of the field. As a result, the expensive seed is not always optimally applied at the right amount, at the optimal planting depth or with the right spacing.

However, because air springs do not require oil, they are already an increasingly sought-after alternative for hydraulic technology. And when equipped with HPTA sensors, up to 56 planting rows can be individually calibrated with high precision at the touch of a button following an initial ground scan. “In addition, they can automatically adapt as they go along and compensate for different soil conditions,” says Carsten Klages, pointing out the potential. This means that seeds can be disseminated just as deeply in loose topsoil as in firm soil.

This precision becomes even more important with field sprayers. Because regardless of irrigation or fertilisation: if liquids unevenly concentrate in one place while missing elsewhere, it can jeopardize an entire harvest. Here, too, smart air springs can ensure that each individual plant gets exactly the right amount of water. In addition to the different soil conditions, our sensors detect changes in the vehicle weight, which continues to decrease over time as the liquid is discharged from the tank. Manually adjustable air springs have also been used for this purpose up to now, which could gain in precision by using HPTA sensors.

No longer a distant future: Agriculture 4.0

In the last ten years, agricultural technology has developed greatly with the help of digitalization, and I expect this to continue,” says Carsten Klages, looking to the future of agriculture. Today, aerial drones are already a frequently used means of land inspection, 360-degree camera systems attached to agricultural machinery, such as Continental’s ProViu 360, give farmers a good overview of their surroundings, and modern harvesting machines are monitored and kept operational with the help of predictive maintenance. Therefore, Integrated Sensor Technology will continue to drive development and further increase automation, safety, sustainability and efficiency on farms. Farmers will then no longer perform many tasks themselves and by hand but will monitor the machines from their offices. After all, the sensors have the necessary feel.

Incidentally, Toni the logging horse is also benefiting from digitalization. Because in keeping with Continental’s 150-year tradition – the first product was a hoof buffer made of rubber – we are now presenting a unique hoof shoe for the first time. This is pulled over the horse’s hoof and an integrated sensor provides indications of irregularly distributed pressures on the sole. This allows blacksmiths to intervene at an early stage before health problems arise and, down the line, require time-consuming and expensive veterinary treatment. In addition, the data from the hoof shoe sensor facilitates diagnosis and thus the optimal direction of therapy. “Maybe we will become livestock professionals after all,” says Carsten Klages