The importance of lighting and LED technology is often underestimated. Achieving good lighting solutions requires knowledge and consultation with a professional. Leading lighting specialist TYRI knows a thing or too about the right lighting for off-highway. By considering the following points when making a purchasing decision, better lighting solutions will be achieved overall…

***

Luminous intensity

Lumen output – theoretical or effective – that’s the big question. Each LED has a theoretical lumen output specified by the LED manufacturer.

A TYRI LED work light reaches its operating temperature after 30 minutes, only then do we measure effective lumens. All LEDs have a lower efficiency at higher temperatures and the loss amounts to about 5%. Additionally, losses through optics amount to 20%, resulting in an effective lumen output of 75% of the theoretical value.

Mass-produced products often only provide theoretical values. Their effective lumen output fcan vary from 40-50% of the theoretical value. This shows how important it is to distinguish between theoretical and effective values.

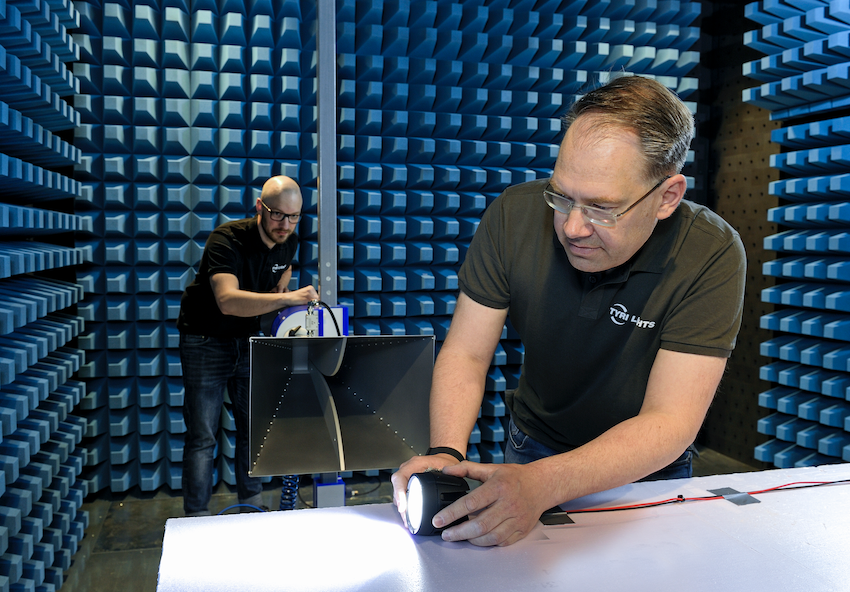

ABOVE: TYRI’s EMC test lab in Sweden

Price

With the above knowledge about theoretical and effective lumen output make sure that your first step is to compare LED worklights correctly.

Colour temperature

High colour temperature (>6000K) produces a cold white light, almost blue in appearance, which can cause significant eye fatigue. It is often chosen for its brightness but is not suitable for prolonged use. Additionally, this colour temperature creates excessive glare and reflections on dust, particles, rain and snow.

Electromagnetic compatibility (EMC)

When selecting an LED work light, it is important to consider its Electromagnetic Compatibility (EMC) rating. If the light has no EMC classification or a low rating, it can result in radio interference. In more severe cases, it can lead to a complete halt to your mobile machinery.

Vibrations

It is crucial to ensure that the chosen LED work light is capable of withstanding vibrations caused by your mobile machinery or uneven ground. Failure to do so may result in the bracket cracking or the components on the PCB becoming loose, once again leading to failure.

Light quality

Poor light quality is indicated by the presence of hotspots, circles, shadows, and varying colour temperatures. The eye is naturally drawn to the brightest point in the field, which in this case is the hotspot. The uneven light distribution can cause irritation to the eyes and limits visibility.

Working area

Before purchasing an LED work light, consider the area you wish to illuminate (length and width), and the intensity of light needed.

Too much light

Using an LED light with a high lumen output on a short distance can lead to intense bright spots and the creation of glare. The highest lumen output is not always the right solution for every application. Start to judge a work light by the light distribution and how much area one light covers instead.

Incorrect placement

Selecting the wrong position or height for the light, often coupled with excessive brightness,

can cause hotspots and glare.

Open reflectors

LED work lights with open reflectors and a clear lens, where the light emitting LEDs are visible, can cause various issues such as excessive glare. Glare not only limits visibility but also causes eye fatigue.

Sustainability

Purchasing a product that matches your applications requirements is the most sustainable option, generating less waste ending in landfill due to short working life of low-quality parts.

For assistance in designing the best solution for your vehicles, contact TYRI. iVT