As the use of electric motors in off-highway powertrains increases, it is crucial for manufacturers to develop a robust and stable stator welding process, because the connections between stator steel plates and stator coils are essential for reliable engine performance. The stator is the stationary part of an electric motor – an electromagnet made up of a core and magnetic wire. The stator core is used primarily to keep the magnetic field aligned. It is made up of many individual silica-steel laminations. The material is typically between 0.35 -0.50mm thick and coated with a very thin layer of insulation, as little as 0.025 mm. Laminating the core steel and insulating each layer makes any undesired circulating currents significantly smaller and more controllable. Most electric motor stator applications like off-highway powertrains call for connection of this insulated magnetic wire to itself, to contacts (lead frames) or to electronic components outside the motor.

For off-highway powertrain manufacturers, it is vital to devise a stator welding process and equipment that guarantee 100% process quality in a full off-highway powertrain production line. Optimal space usage inside the motor is facilitated by innovative welding equipment, contact designs and process optimization. This allows the designer to reduce a motor’s build height for a space and weight advantage.

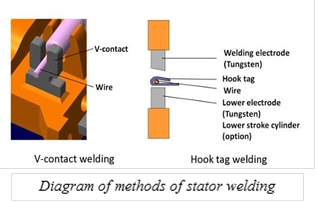

Types of Stator Welding

Off-highway powertrain stator welding engineers typically begin the optimization process by focusing on the mechanics of making a single good connection. However, these mechanics change depending on the type of wire used and the type of weld equipment, among other differences.

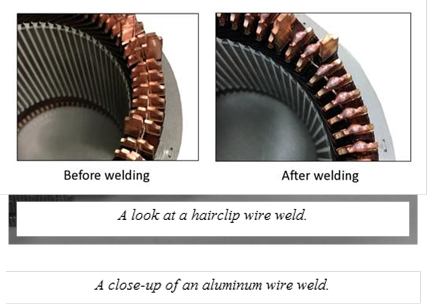

One kind of wire that must be approached in a unique way is the ‘hairclip’ wire, a nickname for the thick insulated wire bent into a C shape. In industries with high production volumes, laser welding is one of the most frequently used technologies for hairclip welding of thick wires.

A typical stator has a ring of coils of conductive wire and the contacts to which these need to be connected. Each of the coil wires is insulated with a lacquer coating. The coil wire is relatively stiff and thick and has a square or rectangular shape. These insulated magnetic wires are bent into a C-shape, also called a hairclip. About a hundred of these hairclip wires must be welded on each end to its neighboring wire in an electric motor.

The hairclip wire can be stripped of its insulation before welding. Though not strictly necessary for the welding process, stripping the wire will prevent oxidation or charring of the insulation. This occurs over a length of about 5 millimeters (mm).

Depending upon the motor design, carbon from the oxidation/charring could move into the motor and cause problems. The magnetic wires are made of copper, which is a challenge for a conventional near infra-red (NIR) laser, which emits at wavelengths of 1,064-1,070 nanometers (nm). At room temperature, copper does not absorb the laser light very efficiently. Concentrating the laser light in a very small spot is the most efficient way to solve this issue.

With power levels up to 5 kilowatts (kW) concentrated into spots as small as 20 microns, the power is so intense the copper heats up almost instantly, resulting in high and stable adsorption of the laser light.

Another challenge encountered in off-highway powertrain stator welding is a direct weld of aluminum wire. This process can be difficult. First, aluminum has very little electrical resistance, which makes a resistance weld challenging. Second, aluminum has an aluminum oxide skin, which melts at a much higher temperature then the aluminum itself: 2.072 versus 660˚C. Because of this disparity, once the high melting aluminum oxide skin is breached, the aluminum underneath transforms to a thin fluid which needs to be contained to prevent blow-out.

An alternative to resistance welding aluminum is laser welding, but this process has its challenges as well, as aluminum is highly reflective, so the laser light from the welder is only partially absorbed into the metal. In addition, as with resistance welding, the aluminum oxide layer causes similar problems.

To get around these difficulties, product designers need to look for alternative methods. One method is hot crimping, discussed in detail below. A similar method can be used with laser welding. The aluminum wire(-s) are sandwiched between two foils or a folded plate. The foil or plate which is on the side of the laser beam is then melted. This melted foil creates a volume of molten material, which melts together with the aluminum wire.

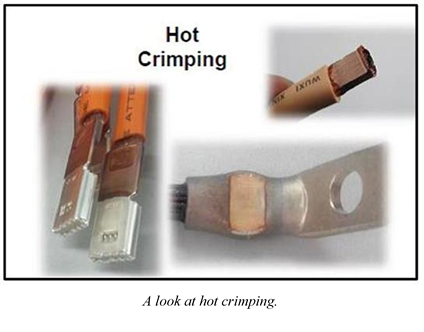

Hot crimping

Hot crimping

Another method that can be used for off-highway powertrain stator wire welding is hot crimping. The hot crimping process has seen a recent surge in use due to the increased electrification in vehicle design. Hot crimping allows joining of wires to one another, or to terminals. The basic hot crimping process consists of placing a conductive metal sleeve, hook, fork, or other shaped object around the copper wire or magnetic wires that are to be joined. The sleeve or other metal object is then placed between the two electrodes of a resistance welding system. A large amount of current is passed through the sleeve, causing it to heat to approximately 500˚C. This temperature is adequate to burn away the enamel or organic isolation and allow it to push gas out of the metal sleeve. Once the isolation has burned away, even more heat is applied to the sleeve via electrical current, which causes the metal sleeve to collapse and tightly compress the stripped copper magnetic wires. Once the compressed ring cools down, there is a strong mechanical and electrical connection between the individual wires and to the metal ring. The metal ring, which is often part of a cable shoe, can then easily be joined or directly connected to a terminal.

Hot crimping creates an excellent mechanical and electrical connection, particularly when more than one wire is being joined together, due to the compression of the heat-collapsed metal on the wires. This connection effectively seals the join from the environment, unlike in cold crimping, which can be critical in corrosive environments. The hot crimping process is far more efficient in terms of cost, time, and effort than other wire stripping and joining processes, because it combines the separate steps of stripping and joining into one automated process. Process control is key to validation of this process. A good hot crimping system measures and controls at minimal displacement, current, voltage, and then logs these numbers.

Resistance welding

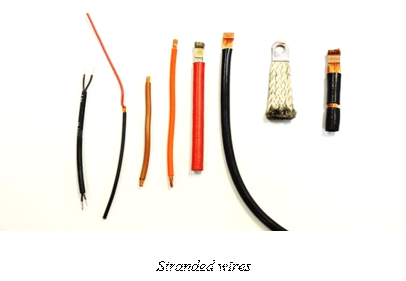

While laser welding might be made to work with aluminum welds for off-highway powertrain welding, it is less suitable in the stranded wire application, as this application features round wires which deflect the laser light like a round mirror. The stranded wire has a relatively undefined shape and a high (and fluctuating) volume of air versus metal.

All of these difficulties are typically present when stranded stator wire needs to be welded.

Resistance welding is a more suitable process than laser welding when stranded wires need to be contacted. In this process, the electrical wire is mechanically stripped from its outer (thick) shielding mantel and placed between two electrodes, which are normally placed vertically, and two electrical isolating guide blocks, which are placed horizontally. The guidance blocks close towards the electrodes to a position where the electrodes can slide in between the guidance blocks. For the second step of the process, the electrodes move towards each other, compressing all of the strands. Once this pressure is applied, electrical current is switched on and the metal is brought to a fusing temperature. This process is called “compacting” or “wire compacting”. The end result is a solid block of metal. In a subsequent process this metal can be either brazed or welded to a part.

Process Control

No matter which method is used to perform off-highway powertrain stator welding, from direct welds, to hot crimping to laser welds, having a high level of process control is important to the continued success of the welding method. For example, during resistance welding, electrodes are in mechanical contact with the parts and compress the product. Electrical current passes through the parts, which generate their own heat. This mechanical contact and active heat generation enables measurements that improve process control and enable in-line quality checks. In addition, electrode clamping force and displacement can be measured. Derived parameters (part presence, part thickness, electrode acceleration, and weld displacement), can be calculated and charted. Voltage and current can be measured and derived parameters (power and resistance, and sometimes part temperature), can be calculated and monitored. Users can log and store data, then go back to that data if abnormalities are detected. This data is essential to optimizing the welding process.

In addition to ensuring the consistent keeping of records and data of welding processes, welding equipment, including both the power supply and the weld head, plays an important role in process control. New weld head technology can further improve and control weld quality. For example, going from foot-actuated, to pneumatic-activated, to motorized weld heads gives more control over electrode closing speed and impact force and prevents over pressure. Set down of electrodes is more controlled, and electrode force and movement can be programmed and better controlled.

Electrode displacement and acceleration measurements can be taken from the weld. Other new measurement possibilities include weld to displacement, in which displacement is continuously monitored during the first few milliseconds and weld current switched off upon reaching a pre-set required displacement. Using the best welding equipment and process monitoring technology can be a huge help to optimizing the welding process in off-highway powertrain stator welding, regardless of the specific welding method or application.

In all, in off-highway powertrain stator welding, making the decision between welding methods is complicated. A close cooperation between the product developer, the application lab, and the joint testing/ qualification department is required to understand how a suitable design can best be developed. Hair clip wires have their own welding process, while aluminum wire can be approached in a number of ways (the most effective usually being hot crimping). Furthermore, stranded wires and direct welds have their own processes. Finding the right process for the material and weld type, and then properly monitoring that process with process control measures and technology, will ensure that manufacturers use a robust, stable off-highway stator welding process.