John Deere Power Systems is gaining extensive and valuable experience of electric drivetrain components as its hybrid wheel loaders log one million hours in the field.

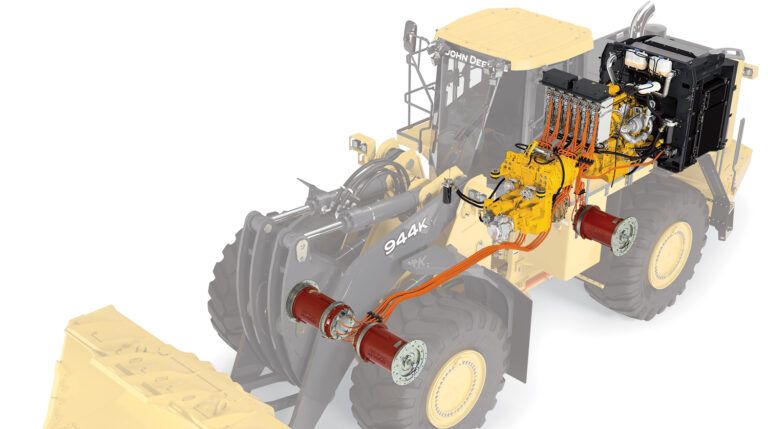

With its 644K and 944K agricultural machines surpassing the operating field hours milestone, JDPS is harnessing the expertise gained from this achievement to develop technologies to reduce emissions, improve fuel economy and enhance machine performance and reliability.

The company introduced its first successfully designed and implemented fully integrated electric drivetrain system at Bauma 2016 but has continued to explore hybrid and full electric solutions since.

“In this emerging market for electrification technology, we are working closely with our OEM customers to understand their application needs,” said Darren Almond, drivetrain product planning manager for JDPS.

“Exceeding one million operating hours shows that John Deere has an in-depth understanding of how to make hybrid drivetrain systems work in the field.

“We can use our expertise to discover innovative ways to develop reliable, efficient, cost-effective alternatives to traditional drivetrain systems.”

Accompanying the two hybrid wheel loaders at John Deere’s stand at Bauma 2019 will be the firm’s new 13.6-liter engine that forms part of its Stage V line-up for industrial and generator set markets.

In addition, the 4.5-liter EWS engine, serving both the 80kVA and the 100kVA markets will also appear at the trade show in Munich, Germany, this April.

Almond added, “Because John Deere has experience managing these interfaces and developing a fully integrated system, OEMs can place their confidence in these solutions.”