Enhance IoT security in the automotive industry by mitigating AI-driven cyber security risks. Discover how industrial grade IoT devices help to protect connected vehicles and connect devices

Every day, companies in the off-highway vehicle market are pushing the boundaries of what is possible. As IoT and AI solutions evolve, industrial vehicles become increasingly connected—and consequently more susceptible to threats. The rapid integration of technologies unlocks new value, but ensuring the security of these critical systems has never been more complex.

Comprehensive cybersecurity defence tactics must be integrated across all connected devices, software, and management systems to effectively protect the entire network.

This article outlines several key security issues in automotive IoT applications and considerations to help you deploy solutions while reducing malicious attacks through robust security measures. A secure-by-design approach ensures that security is not an afterthought but an integral part of the process.

Keep reading to learn what to be aware of and how to implement adaptable solutions while remaining vigilant for potential risks associated with connected systems.

How is IoT used in vehicles?

While the Internet of Things (IoT) is not new, it is revolutionising how industrial vehicles operate, enhancing efficiency, safety, and overall performance. Here’s a look at how IoT is currently applied in off-highway vehicles and what the future may hold.

Common applications of IoT in industrial vehicles

There are many use cases for IoT in the automotive industry. Connected cars and basic telematics have been around since before it was called the IoT market or Industry 4.0. While there are major differences for larger and more expensive equipment, the use cases remain very similar.

- Fleet management: IoT technology enables real-time tracking of vehicle locations, allowing fleet managers to optimise routes and reduce fuel costs. Additionally, sensors monitor vehicle health and send alerts for maintenance needs based on usage patterns.

- Telematics and safety enhancements: Vehicles equipped with IoT sensors collect data on speed, fuel consumption, and driver behaviour. This information helps improve safety through monitoring and coaching.

Future possibilities

While many of these advancements are happening now, they have not yet reached wide adoption across the industry. We are finally starting to deliver on the promises of the past by using smart devices.

- Autonomous vehicles: The integration of IoT with AI is paving the way for fully autonomous industrial vehicles, which could dramatically improve efficiency without human intervention.

- Predictive maintenance: Future advancements may allow for predictive maintenance, where vehicles are serviced before issues arise, minimising unexpected breakdowns and costs. A good example here is hydraulic failures, which are expensive to replace and can lead to machines being sidelined for weeks or months.

- Enhanced connectivity: As vehicles communicate with each other and with infrastructure, traffic flow and safety on job sites will be optimised, creating smarter operational environments. IoT creates massive value by closing the simulation to scheduling accuracy.

- Object detection and collision avoidance: The integration of modern cameras and sensors is vastly improving safety. Job sites are able to mitigate risks to humans and valuable machine assets by detecting in real-time and stopping vehicles even when drivers are unaware of what is nearby.

IoT is transforming industrial vehicles by making them more efficient, safer, and capable of supporting advanced operational strategies. As IoT offers more data to analyse, we will continue to find new advancements.

Benefits of IoT in the industrial automotive industry

By leveraging connected devices, organisations can unlock a range of benefits that enhance their competitive edge and operational effectiveness.

- Enhanced operational efficiency: IoT solutions enable real-time monitoring of vehicle performance and asset utilisation. This allows organisations to optimise processes and reduce downtime. More accurate job costing goes beyond knowing your expenses; it helps companies with the best data lock in new business opportunities over the competition.

- Improved data-driven decision making: Organisations can collect vast amounts of data from their vehicles, equipment, and staff. The industry is increasingly analysing this data as it provides valuable insights into operational performance and maintenance needs, allowing for informed decision-making.

- Increased safety standards: IoT devices contribute significantly to improving safety in industrial work environments. Features such as collision detection systems and environmental sensors help identify hazards and prevent accidents.

- Streamlined communication: IoT enables seamless communication between vehicles, operators, and central management systems. This interconnectedness ensures that all stakeholders have access to critical information when and where they need it.

- Sustainability and cost savings: Implementing IoT solutions can lead to significant cost savings by optimising fuel consumption and reducing waste. Real-time tracking of fuel usage can help identify inefficiencies and promote sustainable practices.

What are the 3 major factors affecting IoT security?

Understanding the critical factors that influence IoT security is essential for organisations looking to safeguard their industrial vehicles from attackers. Here are three major factors that significantly impact security:

- Device vulnerabilities: Weak passwords and outdated firmware can create entry points for cyberattacks. Companies often expose themselves by not changing manufacturer default usernames and passwords. Public static IPs are convenient for remote access; however, they compromise hardware-based security efforts and can pose significant security flaws with even basic ping attacks overloading devices and networks.

- Network security: The interconnected nature of many IoT devices means that a data breach in one area can compromise the entire network. Consider private networks for larger projects; in applications such as mining and forestry, it’s often a requirement given the lack of cellular coverage. Even urban construction can work with existing carriers in their area but should request a virtual private network (VPN) to ensure their assets are not exposed to the public internet. This maintains best IoT security practices while ensuring each device gets proper bandwidth.

- Human factors: Human error remains a significant risk to IoT security. Providing regular training helps staff recognize potential threats to security. Well-documented security policies for OT (Operational Technology) and IT (Information Technology) must be implemented. It’s crucial to keep IT networks separate from connections with OT assets.

By understanding these potential security issues, organizations can take proactive steps to enhance their IoT security posture.

Why is it critical to secure IoT devices?

As industrial vehicles increasingly rely on IoT technology, reducing the risks associated with connected vehicle devices is paramount. The stakes are high, and the implications of inadequate security can be severe:

- Protecting sensitive data: Protecting sensitive data is crucial, particularly in the context of automotive IoT security. IoT devices handle sensitive information, including operational data and maintenance records. A breach could expose this data, leading to financial losses and reputational damage.

- Maintaining operational integrity: Weak security can disrupt operations, leading to significant downtime. Unplanned interruptions have a ripple effect on other aspects of business; reduced tool availability can even take a toll on team morale. Talent is a premium these days, and operational disruptions can lead to increased turnover rates among skilled personnel.

- Regulatory compliance: Many industries face stringent regulations regarding data protection such as the General Data Protection Regulation (GDPR) and California Consumer Privacy Act (CCPA). Prioritising IoT security helps ensure compliance while safeguarding assets. Maintaining modern emissions standards without IoT devices collecting data and aiding in compliance may require manual processes that are labour- and time-consuming.

- Mitigating financial risks: The financial implications of a breach can be staggering. Added costs go beyond downtime to include audit expenses, incident response, system recovery, insurance premiums, and implementing new security systems to prevent future events. Investing in security infrastructure proactively mitigates these risks.

- Building trust with stakeholders: Demonstrating a commitment to security fosters trust among clients and partners. When organisations prioritise protection, they signal that they value safety and confidentiality. Once a firm has been negatively portrayed in the press for exposures, it can hinder partnerships and damage reputation.

Safety and security are critical components for longevity; they are not just technical necessities.

The rising threat: attacks on the vehicle industry

Modern vehicles now come equipped with numerous advanced systems, increasing complexity. However, retrofitting new technology onto existing assets alongside proven older systems can provide more entry points for potential threats. Understanding these risks is essential for effective risk management.

Unlike consumer automotive technology, compromised industrial vehicles can pose much larger risks to the public due to their size and power. Protecting these systems is vital for maintaining operational efficiency and ensuring safety.

Threat landscape

Hacking

- Unauthorised access: Industrial IoT devices are prime targets for hackers aiming to gain unauthorised access to sensitive systems. Weak passwords, insufficient authentication, and outdated software can create vulnerabilities that allow attackers to control critical machinery or vehicle subsystems.

- Exploitation of vulnerabilities: Hackers often exploit known gaps in devices or software. For example, if an industrial vehicle’s ECU runs on outdated firmware lacking recent security patches, it becomes an attractive target for cybercriminals.

Ransomware attacks

- System lockdown: Ransomware can encrypt critical infrastructure data and demand ransom for decryption keys. In industrial settings, this can lead to operational paralysis, halting essential logistics operations.

- Extended downtime and recovery costs: The consequences of a ransomware attack extend beyond immediate financial losses; organisations often face prolonged downtime while recovering systems and data.

AI-enhanced attacks

AI will pose significant security threats as IoT devices face an enormous challenge keeping up with its pace. Security patches for IoT will need to be more frequent as part of a holistic approach to system security.

- Automated attack tools: Bad actors increasingly leverage AI to develop sophisticated automated tools that rapidly scan for weaknesses across large networks.

- Training data manipulation: Attackers can introduce malicious data into the training sets of machine learning models used in vehicle systems, causing models to make incorrect decisions or predictions.

- Sensor data manipulation: By feeding false data to sensors (e.g., GPS, speed, or environmental sensors), attackers can mislead vehicle systems, potentially causing unsafe operations or accidents.

- Adaptive malware: AI enables malware to adapt its behaviour based on system responses, making detection and prevention more challenging.

Mitigating IoT security vulnerabilities

Organisations can implement several effective strategies to minimise IoT security risks:

- Conduct regular security audits: Regular assessments help identify vulnerabilities within IoT systems. Continuously evaluate the effectiveness of your IoT security solutions.

- Implement strong access controls: Establish stringent access measures to prevent unauthorised access; two-factor authentication is still considered best practice.

- Utilise encryption: Encrypt data both at rest and in transit to protect sensitive information—especially concerning IoT device security. When possible, process as much data as close to the source as you can.

- Regularly update software and firmware: This cannot be overstated; updates at the hardware, software, and application levels ensure the security of IoT devices against emerging threats.

- Develop an incident response plan: Prepare protocols for detecting and recovering from security incidents tailored specifically for your organisation’s IoT devices.

- Foster employee awareness and training: Keep your team informed about necessary security protocols for protecting connected assets and IoT devices. Training is critical to help staff recognise potential threats and participate in reporting incidents.

- Monitor network traffic: Real-time monitoring detects suspicious activities indicative of an attack on the security of IoT devices. Keeping historical records of device data consumption not only helps manage costs but also provides insights using anomaly detection.

By adopting these strategies, organizations can significantly reduce their exposure to additional security risks while enhancing safety in an increasingly connected world.

Hardware-based automotive IoT security

Edge computing

Embracing edge computing enhances security by processing data closer to the source –right on the vehicle itself or very nearby. This minimises data transmission over networks, lowering the risk of interception while enabling real-time anomaly detection. By analysing data locally, organisations can quickly respond to potential threats, bolstering overall security.

Secure boot and TPM 2.0

Implementing secure boot processes and utilising Trusted Platform Module (TPM) 2.0 are essential steps in safeguarding industrial vehicle systems. Secure boot ensures that only trusted software is loaded during startup, preventing unauthorised access from the outset. Similarly, TPM 2.0 adds hardware-based security features that protect sensitive data and maintain system integrity, making it much harder for attackers to compromise critical functionalities.

CAN FD SIC

Using CAN FD SIC (Single Integrated Circuit) offers enhanced security and efficiency compared to standard CAN protocols. This advanced communication mechanism supports larger data payloads and faster transmission rates–crucial for modern vehicles—and its improved error detection capabilities help ensure that data integrity is maintained while reducing communication errors that could be exploited by cyber threats.

Approach to software security strategies

Linux open-source solutions

Utilising Linux-based systems provides flexibility along with robust security features due to its open-source nature allowing continuous improvements and rapid patching of vulnerabilities—ensuring resilience against emerging threats.

Regular software updates

Keeping software up-to-date is vital for protecting against known vulnerabilities. Regular updates equip all devices with the latest security patches—shielding them from potential attacks—and adopting a proactive approach helps reduce exposure to cyber risks significantly.

MQTTs for secure communication

Employing MQTTs (Message Queuing Telemetry Transport) facilitates secure data transmission between devices and cloud management systems designed for low-bandwidth environments while providing enhanced features that help protect sensitive information during communications.

CoreM2M helps secure networks at scale

As organisations navigate the complexities of cyber IoT security in industrial vehicles, CoreM2M provides a strategic advantage with tailored solutions designed to enhance security along with operational efficiency:

- Connectivity solutions: We offer robust IoT connectivity solutions that enable seamless communication between connected devices while our international IoT data plans ensure your industrial vehicles stay connected for real-time monitoring.

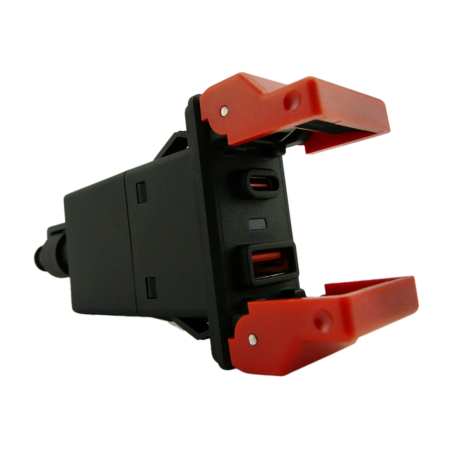

- Vetted and certified hardware: We ensure that hardware includes essential cyber threat security features like Secure Boot and TPM 2.0 while also ruggedized for harsh environments.

- Advanced management platforms: CoreM2M provides secure management platforms that allow companies to confidently scale IoT networks while maintaining control over their devices.

- Custom software development: Our custom software development services optimize your IoT deployments by integrating seamlessly with existing systems—expediting your time-to-market by handling sub-sections of projects or providing single-source solutions.

By leveraging these tools alongside our expertise at CoreM2M equips organisations effectively enhancing their IoT security posture while navigating challenges in a connected world while safeguarding operations.

Final thoughts and insights

The industry surrounding industrial vehicles along with IoT technology will continue evolving; understanding addressing these challenges becomes more critical than ever—from unauthorised access through AI attacks—these risks significantly impact operational efficiency along with safety.

By implementing effective strategies such as embracing edge computing leveraging Linux open-source solutions utilizing VPNs ensuring robust device management practices organisations enhance their security posture further through advanced hardware features like Secure Boot TPM 2.0 strengthening defences against potential threats.

At CoreM2M we are dedicated to providing customised solutions addressing challenges head-on utilising our connectivity solutions custom software development services alongside hardware designed safeguarding you gain access expertise necessary navigating complexities ensuring safety efficiency resilience increasingly connected world.

As you move forward securing your industrial vehicles remember staying informed proactive key together let’s ensure operations remain safe efficiently resilient interconnected landscape ahead!