To support the use of hydrogen as a climate-friendly energy carrier, Hengst has developed a modular system of various filtration solutions for commercial vehicles and off-highway applications. This consists of ion exchangers and cathode air filters for fuel cells, as well as disc separators and active crankcase ventilation for hydrogen combustion engines, which ensure the service life, efficiency, performance and safety of the drive even under harsh operating conditions.

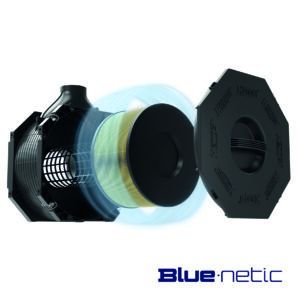

The coolant of a fuel cell is enriched with ions during operation. These are caused by aging products of the coolant itself or by components in the cooling circuit. Effective filtration is therefore required for the safe operation of the fuel cell. The Blue.iox ion exchanger from Hengst offers particularly high protection with minimal maintenance. The unique design of the filter cartridge with axial filter flow and the special mixed bed resin system for cation and anion exchange ensure high filtration performance over the entire service interval.

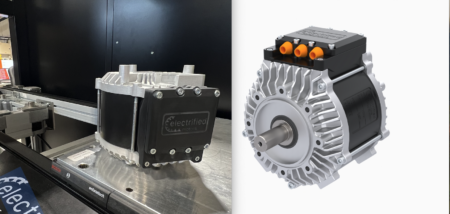

Special requirements are also placed on filtration in the air circuit of a fuel cell. The intake air must be very effectively cleaned of particles from the outside air to ensure long service life and high performance. In addition, pollutants such as nitrogen oxides (NOx), ammonia (NH3) and sulfur oxides (SO2) can lead to unwanted deposits in the fuel cell and damage it. A specially developed cathode air filter system Blue.netic from Hengst with a multilayer structure reliably protects the fuel cell components from particles and harmful gases.

The requirements for filter systems for hydrogen engines are comparable to those for conventional gasoline or diesel engines. However, the increased introduction of water into the engine oil and the easy flammability of hydrogen must be considered as additional challenges. Blowby gases that enter the crankcase via the cylinders form an explosive mixture at concentrations above 3.5% by volume, which ignites on hot engine components. The active ventilation system developed by Hengst minimises the hydrogen concentration in the crankcase and counteracts the risk of ignition.

The wide world of filtration

As a family operated company with 3,600 employees at 25 locations, Hengst Filtration is known worldwide for its innovative filtration and fluid management solutions.

Our products are used in millions of applications around the world to make something cleaner. But we can do even better. We think filtration – in everything we do. We deliver leading edge filtration systems for the fields of plant and machine engineering, industrial filtration, hydraulics, life science and health care. Our custom-tailored solutions are used in medical cleanrooms, air conditioning systems, cleaning machines, industrial systems, electric tools and robots.

We are also an OEM supplier for the international automotive and motor industry and a development partner for sustainable drivetrain and mobility concepts.

Making our planet a purer place

Mobility, health, economy, environmental protection and sustainability: our daily work focuses on the major issues of our time. With the goal of making the planet a cleaner place. This enables worldwide forward-looking technologies in all industries.

EIMA International attendees can visit Hengst at Hall 15 / Booth A10.