Cummins has shown off the final stages of a £25m refurbishment of its turbocharger factory in Huddersfield, and highlighted two products in development to support its customers on the road to net zero.

The company reported that an unnamed vehicle OEM is planning to launch an internal engine combustion vehicle in 2025-2026 running on hydrogen rather than diesel. What is envisaged is a spark-ignited engine using a conventional engine block, with an engine head adapted for hydrogen. (Last year it launched the concept, including the 15-litre X15 engine with heads for diesel, natural gas or hydrogen gas fuel; US versions will burn gasoline or propane).

At a technical press day in Huddersfield, UK, earlier this month, Cummins shared these figures: a 15-litre, 450hp hydrogen-powered engine offering 500 miles of range from 80kg of hydrogen stored at 700bar. It said that this vehicle would be 2,500 lbs (1,134kg) heavier than a comparable diesel Class 8 sleeper cab truck, referring to the American designation of an artic, and blamed the weight premium on the hydrogen storage tanks.

Engineering issues in the project include the lower calorific value of hydrogen (even when highly compressed), material choices – as hydrogen can cause embrittlement of vulnerable materials – and the inevitable production of NOx during combustion. For the latter reason, a relatively simple emissions aftertreatment system, such as employed for natural gas trucks, is expected.

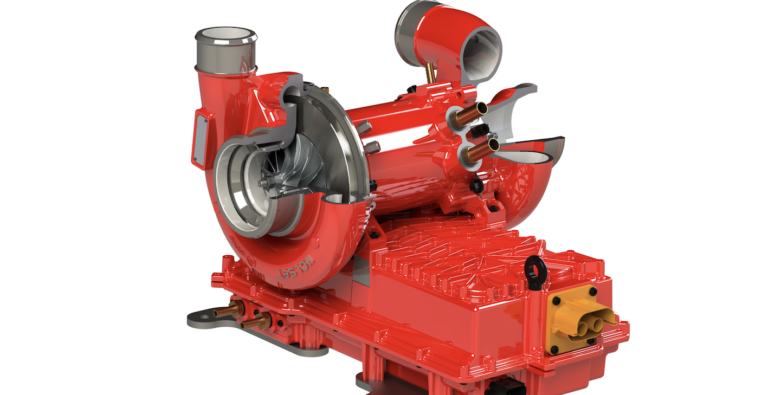

Development of this engine concept has been supported by work by the Brunel project, an R&D consortium including Cummins (based in Darlington), BorgWarner, Johnson Matthey and Zircotec, which has received £14.6m of government funding. It claims to have logged 3,000 test hours worldwide. In the UK, Ricardo has supplied the project with a one-off test engine, following its own work at the University of Brighton. Helping to boost combustion in the hydrogen ICE will be a high-performance turbocharger. Ideally, it would be a single-stage, variable-geometry turbocharger, but a two-stage unit is more likely, as it will need to provide the right transient response, company experts said.

A new turbocharger for hydrogen fuel cells which is claimed to help increase power capacity is also in development. Heavy-duty applications would require large fuel cells; the more air pumped into the cell, the more oxygen is available to combine with hydrogen to make energy. Compressors consume energy though, so a turbine in the exhaust stream that can recover kinetic and thermal energy is proposed to reduce the total energy drain. Such a product is now being developed as part of a collaborative R&D programme, Project Trident (with partners the University of Bath, Holtex and Aeristech). A first demonstrator has been developed, and a second is due by the end of the year, when the project winds up.

Cummins contends that a 48V DC model rated at 45kW capacity can regenerate 25kW of energy from the waste stream, providing 70kW of energy to facilitate a more powerful fuel cell than currently offered, theoretically 250kW. It says that this would be possible despite a much lower combustion temperature (100degC compared to 650degC), as well as a more humid gas stream. Still, the savings could offer 8% overall fuel savings, Cummins reports. 48V e-turbos in wastegate and variable-geometry designs are in development.