The Association of Equipment Manufacturers’ (AEM) Hall of Fame celebrates the men and women who create the equipment and technologies that build, feed, and power our world. Among its members are individuals who have not only changed the way the equipment manufacturing industry works, but the way the world does. Here are five of the biggest names and innovations

***

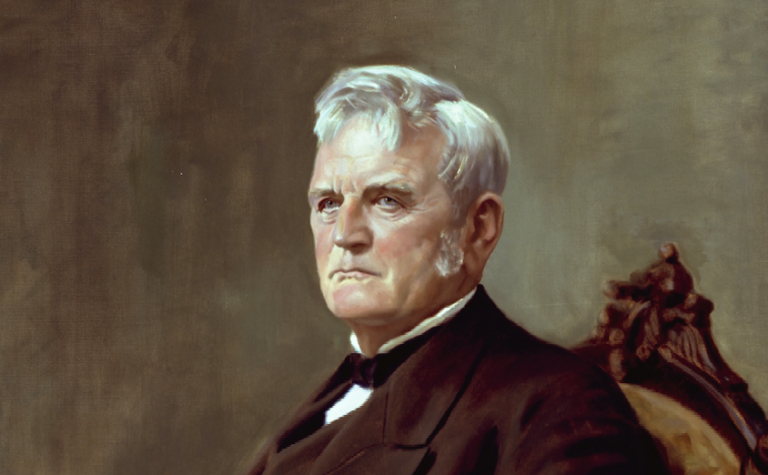

John Deere (inducted 2012) | Deere & Co. | self-scouring moldboard plow

One of the reasons sandwiches have remained in such ready supply worldwide has to do with the next AEM Hall of Fame member, John Deere, who opened up “America’s Breadbasket.”

When Deere first moved from his home state of Vermont to his adopted home of Illinois in the 1830s, the grasslands of the American Midwest frustrated farming efforts, as the native grasses’ deep root systems created sticky, difficult fields to work compared to the looser, forest-based soils then-new European settlers were used to. Every few feet, farmers would have to clear off the mud from their wooden or cast-iron plows before proceeding.

Deere started tinkering with a Scottish saw blade made out of harder, smoother steel in 1837. The smoother steel surface, combined with the sharper angle Deere perfected, allowed his new plows to cut the prairie sod, and allow for the use of some of the most fertile, productive soil in the world.

Eventually, Deere’s plows would be known as “The plow that broke the plains,” and create America’s Breadbasket in the Midwest.

William Smith Otis (inducted 1996) | steam shovel

Deere isn’t the only one famous for breaking literal ground. William Smith Otis only lived to be 26 years old, but in his short life, his invention of the steam shovel started transforming the world by allowing for faster construction of railroads, canals, and other forms of infrastructure we take for granted today.

Otis’s design was intended to mimic the same action of a human using a shovel, in which it would excavate a bucket of earth, turn up to 180 degrees, dump it into a receptacle (such as a railcar), then return to position. Otis’s shovel was mounted on a rail platform, powered by a steam engine, and used chains to control the bucket.

Otis was granted a U.S. Patent (No. 1,089) in 1836, but tragically died less than three years later of typhoid fever.

Cyril & Louis Keller (inducted 1999) | Melroe Manufacturing/Bobcat | skid-steer loader

While Otis’s steam shovel loaded dirt, brothers Cyril and Louis Keller got their big break loading turkey waste more than a century later. In 1957, the brothers were tasked by their turkey-farming friend in Minnesota to help him mechanize the process of clearing the manure out of his large barn. What would result from that challenge, a compact front-end loader that could turn fully around within its own footprint, would create one of the most versatile machines introduced to the jobsite and barnyard since the gasoline-powered tractor.

After the concept was purchased by Melroe Manufacturing of North Dakota, the Keller Brothers were hired to continue developing their three-wheeled concept. It was at Melroe where the Kellers added the fourth wheel and the skid-steering mechanism, allowing the machine to turn with differential steering like a military tank, and gain a significant stability boost from the extra wheel, resulting in the first zero-turn skid-steer, the Melroe M-400. Eventually, the concept of a compact loader would develop into the track-loader by replacing the wheels with tracks, giving the machine even greater ability to do work.

Benjamin Holt (Inducted 1993) | Holt Manufacturing/Caterpillar | track-type tractor

Those first working tracks come courtesy of Benjamin Holt, who patented the first workable continuous-tracked tractor at his shop in Stockton, Calif.

A year after seeing a number of non-functional concepts on a trip to England, Holt developed his own ideas and tapped his company’s metallurgical knowledge to produce a working crawler-tractor concept in 1904.

As the story goes, while Holt was testing his steam-powered “No. 77” prototype by plowing the marshy soil of Roberts Island, near Sacramento, Calif., his company photographer remarked the upside-down image of the machine in his viewfinder resembled a “caterpillar.” From that day, the machine, and name, were born. Holt’s first steam-powered crawler tractors sold in 1904 for $5,500 (the equivalent of more than $192,000 in 2023), however, the concept really broke through when his nephew, Pliny Holt, started creating gasoline engines for them in 1908.

Bryn Fosburgh (Inducted 2022) | Trimble, Inc. | Real-Time Kinematic (RTK) GPS Technology

Before Global Positioning Systems (GPS) incorporated RTK technology, using GPS to figure out where something was on the surface of the Earth took a backpack, a receiver that often resembled half a softball on top of a large walking stick, some patience and the ability to compensate for it’s ability to only calculate position within five meters (yards), though later iterations were able to condense that to thirty centimeters (approximately one foot).RTK technology, however, allowed receivers, now significantly miniaturized, to track position of a receiver in real time within one centimeter (less than half an inch). With this advancement, GPS was able to surpass its original design of tracking large military assets like aircraft carriers, to allowing a tractor to precisely plant a field on its own, allow a road grader to accurately grade a new road curve or even guide a person accurately to their favorite sandwich shop.

***

The AEM Hall of Fame recognises even more people who changed the world with their ideas and innovations, and is accepting nominations for 2023 until Friday, June 16. To submit a nomination for consideration, click here to fill out the form, and tell us their story of innovation, industry contribution, leadership, and social responsibility.